Warehouse Operations

On enabling multi-warehouse in your organization, the following warehouse-based features and operations are unlocked:

- Tracking goods across various storage locations

- Performing inventory transfers between warehouses

- Selecting a warehouse for dispatching/receiving the goods

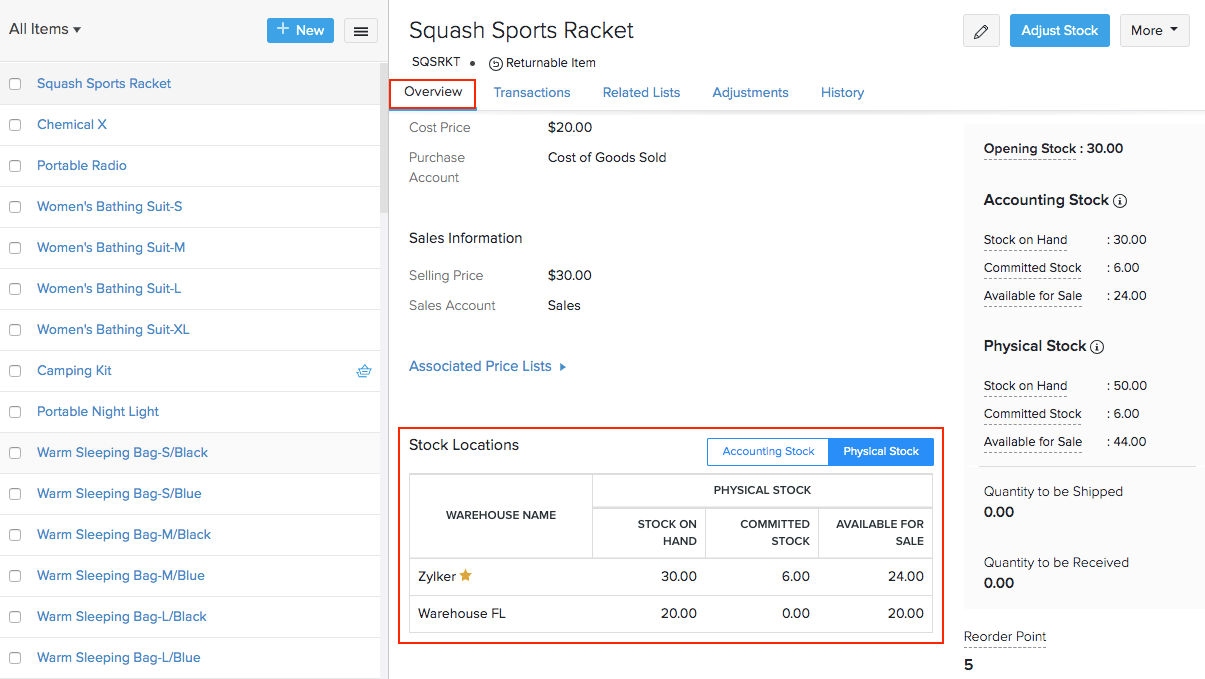

Tracking goods across various storage locations

In the overview page of an item or a composite item, you will be able to view the the distribution of available stock across different warehouse locations.

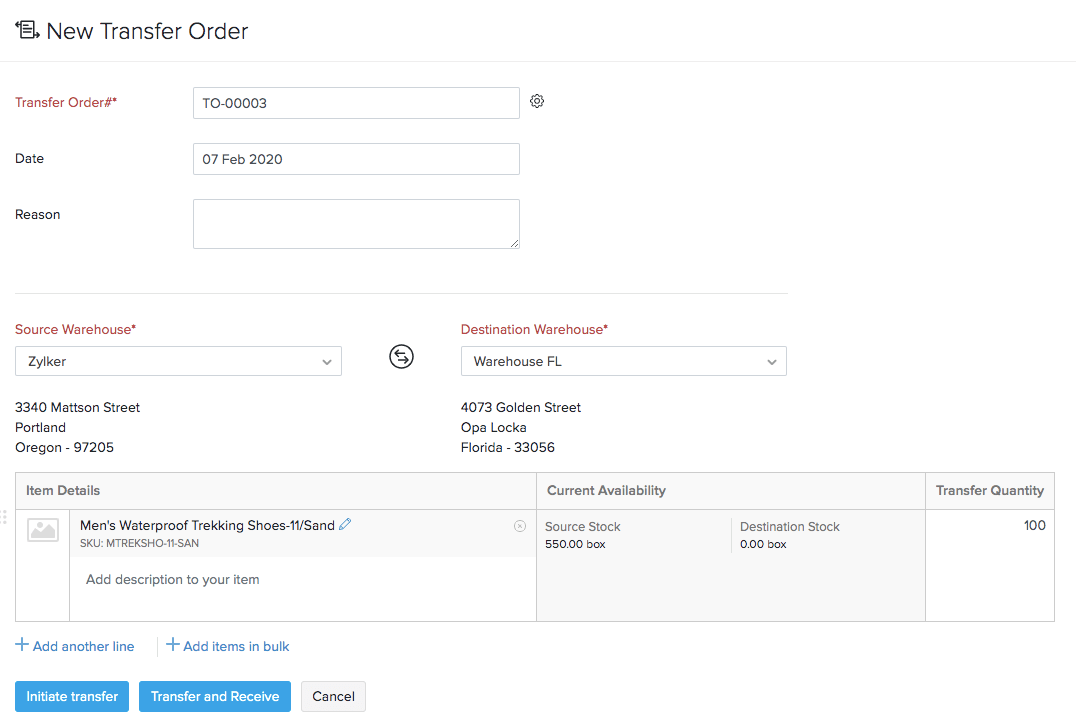

Performing inventory transfers between warehouses

The opening stock that you enter for an item or composite item is always stored in the primary warehouse. If you require stock elsewhere, you can issue a transfer order to move your goods between warehouses.

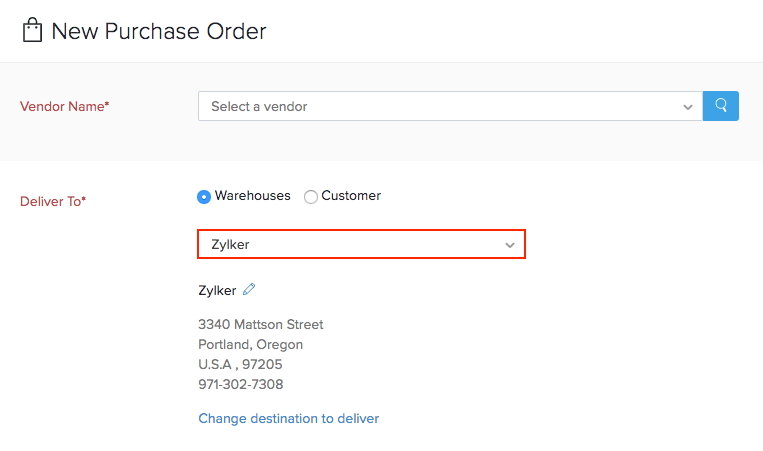

Selecting a warehouse for dispatching/receiving the goods

- In purchase orders and bills, you can select the preferred warehouse to which your purchased goods has to be delivered. However, it is not possible to have each item delivered to different warehouses.

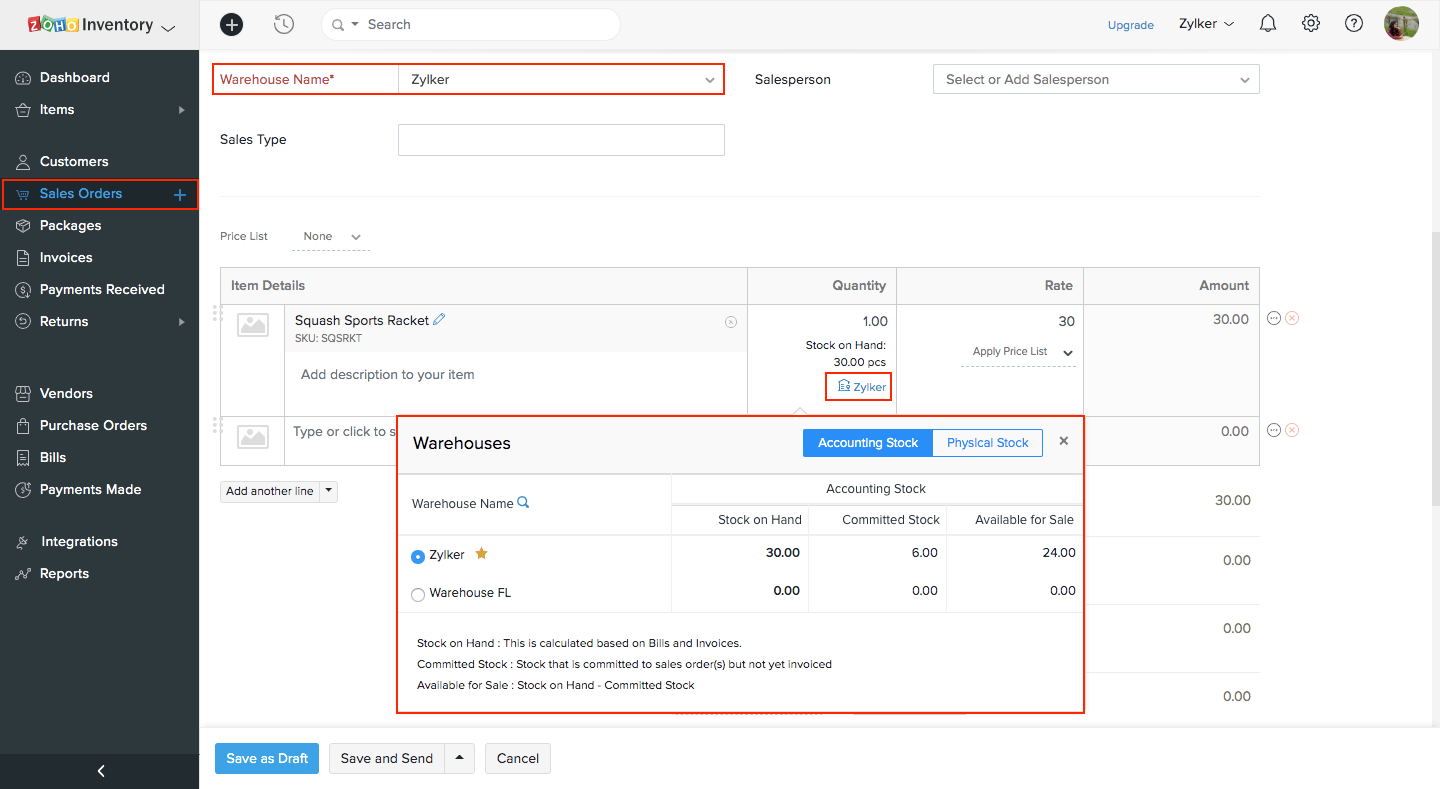

- In sales orders and invoices, you can select the warehouse from which you want to dispatch the goods. You can also select a different warehouse for an item if there is not enough stock.

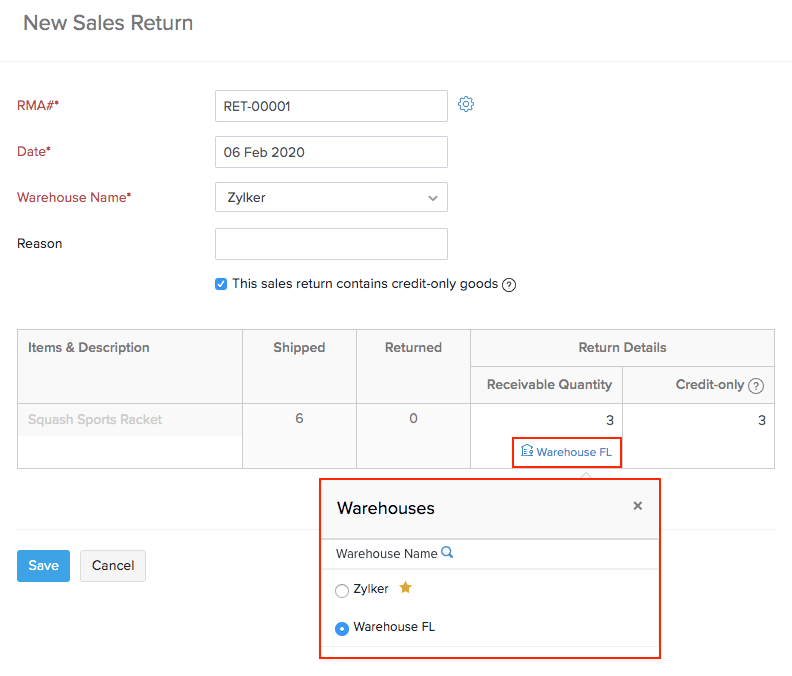

- While recording sales returns, you can select the warehouse where you want to deposit the returned goods.

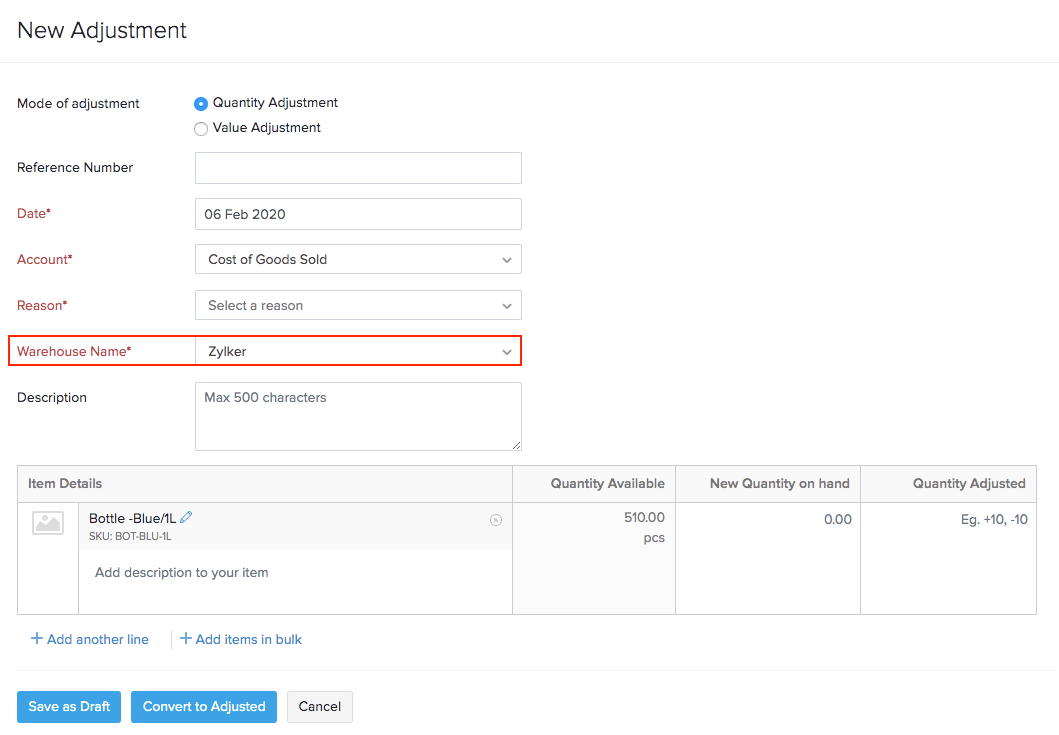

- While making inventory adjustments, you can select the warehouse in which you want to adjust stock for an item.

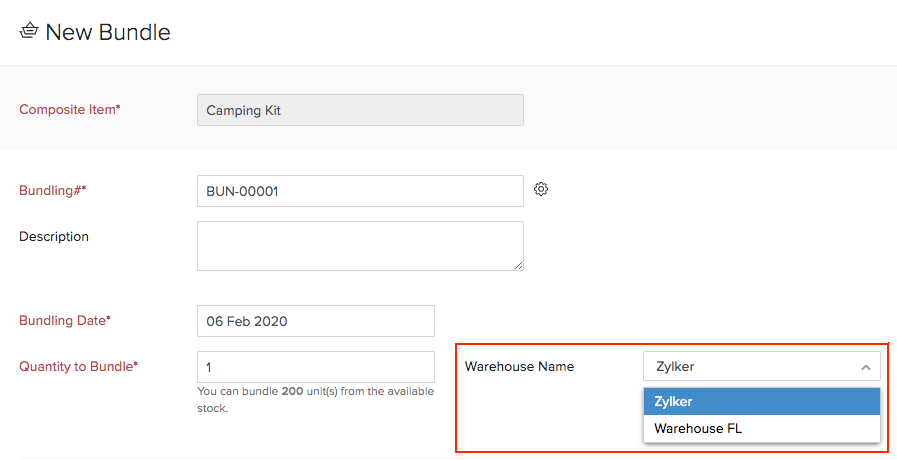

- While creating bundles for a composite item, you can select the warehouse to which the bundles should be added. The bundles that can be created is calculated based on the availability of the associated items in the selected warehouse.

- While importing transactions, you can associate warehouses to them by specifying the warehouse name against every transaction (i.e., every row) in the import file.