Inventory management is a technique of controlling, storing, and keeping track of your inventory items.

Inventory management is an essential component of supply chain management, as it regulates all the

operations that are involved from the moment an item enters your store until it has been dispatched.

To put it in simple words, inventory management helps you streamlining your operations, organize your

resources, and maximize your returns. Read on as we dive deeper into inventory management to find out

how it impacts your organization.

Impact of inventory management

Before we understand how exactly inventory management has an impact on your business, it is essential

that we walk through the levels that make up an organization. An organization is made of three levels —

structure, process, and system. Each of these levels is necessary for the overall functioning of the

organization. The structure determines the crucial elements of the business, the process sets the

sequence of steps that need to be undertaken to meet the organization's objectives, and the system

aligns the elements with the process and solves organizational problems.

Inventory management works at all these levels. To understand the role of inventory management at

each level, let's compare it with the internal functioning of a car.

Structure:

The arrangement of and relations between the parts or elements of something complex.

Inventory management forms the structure for an organization like a chassis frame does for a vehicle.

The chassis frame is the base of a car. It acts as a platform which interconnects different components

like the gear box, engine, wheels, and axles. All of these components are bolted to this frame to hold

the car together. The chassis frame keeps the engine secured and the wheels aligned. In the absence of

a chassis frame, neither the engine nor the wheels can fulfill their objective.

Similarly, inventory management secures the major components of your organization, like Marketing and Finance.

Each of these components has different specific goals. Inventory management keeps marketing goals secured by

ensuring the right items are available at the right time, and it keeps your finances aligned by controlling

the flow of stock.

-

It's a common mistake to separate inventory management from marketing strategy. They may seem unrelated, but a lot of

marketing activities actually rely on successful inventory management. To give you an example, if an organization

decides to distribute a thousand free samples of their new item to three major retailers (A, B, and C) as a promotion,

then they'll need to get the right item to the right place at the right time. So, how does inventory management help?

Let's assume that the items need to reach three different retailers at the beginning of next month. The first inventory

management practice tactic would be to list the schedule of operations in a format like this:

| Operation |

Duration |

| Sourcing |

1 week |

| Manufacturing |

2 weeks |

| Transport |

|

| -A |

3 days |

| -B |

2 days |

| -C |

5 days |

This type of schedule is very helpful for planning your next actions. From this schedule, you get a fair idea about

which delivery has to be made first, when you need to start manufacturing or order from your supplier, and how you will

make adjustments if there is a delay in any part of your plan. If you want to get more detailed, making separate tables

for manufacturing, transportation, sourcing, and so on can help you drill down into the specifics and create a more

foolproof system.

-

Inventory forms a crucial part of accounting and also has an impact on the company's financial goals. Since inventory

management deals with day-to-day activities, refining the inventory process can help cut down on costs for the

organization. It can also release excess funds that can then be used for other purposes. Let's go through some of those

areas and try to identify how inventory management makes an impact:

-

Cash flow refers to the in-and-out movement of cash in your organization. It is calculated based on three major types

of activities: operating, financing, and investing. Cash flow gives a clear picture of the company's cash holdings and

is regarded as a very good indicator of the liquidity of an organization. Cash expenditure in inventory is included

under operating activities, because inventory is used in the day-to-day operation of the firm. The cash flow of a

company can be severely affected if a lot of cash is spent on buying stock that's moved to production at a very later

stage. This affects liquidity and can lead to negative cash flow. Tools like re-order points and the

safety stock formula

can help an organization avoid such situations by ordering items at the right time and minimizing their holding

cost.

-

Working capital is defined as the difference between the company's current assets and its current liabilities. Current

assets include inventory and receivables from customers. Current liabilities include payables and other short-term

obligations. Unlike with cash flow, a low working capital is beneficial for an organization because it means that you

are receiving timely payments from your customers and not spending too much of your funds on inventory. If a lot of

funds are parked in inventory, then the company might need to look for other sources of capital to manage its daily

activities. Inventory management solutions like Just-In-Time ordering (JIT) and the Economic Order Quantity (EOQ) can

help solve such issues.

-

One of the most important reasons for following good inventory management practices is to maintain a reliable record.

In day-to-day business, items can get damaged in transit or lost due to extraordinary circumstances like theft or fire.

Not accounting for such losses makes your financial data inaccurate. If the amount of inventory loss incurred isn't

adjusted in your Cost of Goods Sold (COGS) and also on the asset side of your balance sheet, your statements will show

inflated profit and improper asset valuation. One of the best ways to avoid that is to use inventory management

software, which makes recording inventory and item adjustments easier and less time-consuming.

-

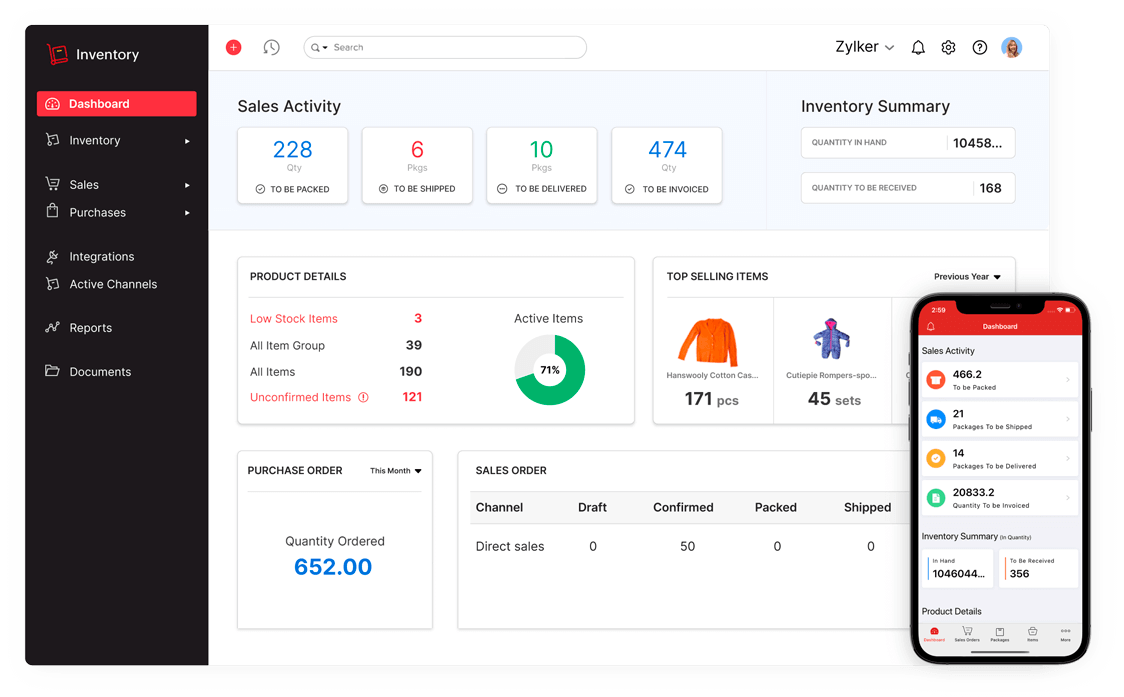

Your inventory management application can have a big impact on the IT infrastructure of your organization. A good

inventory application which integrates with other systems can help you establish a holistic IT solution to fit your

business requirements and manage your inventory and accounting needs concurrently. This kind of integration helps build

a more reliable database, as data entered in one application gets updated in the others on a real-time basis.

Similarly, an application with open API offers a lot of scope to integrate separate applications and customize the

process of managing an operation.

Just like the chassis of a car supports the important components of a vehicle by forming a strong structure, inventory

management supports the three vital functions of an organization: Marketing, Finance, and Information Technology. A

good inventory management strategy aligns itself with the organization's marketing goals, supports its financial

viability, and designs its IT infrastructure.

This importance is even more pronounced when your organization is on a growth stage. With the increase in scale,

inventory management can get overwhelming and difficult to control. In such cases, the best results can be achieved

with the help of good inventory software.

Process:

A series of actions or steps taken in order to achieve a particular end.

A vehicle is set into motion when certain processes are triggered successfully.

When you turn the key to the on mode, the spark plugs connect with the battery and

ignition coil, the electric motor cranks up the engine, the power gets supplied to the

wheels, and then you are off. This entire process is a series of actions performed by

individual units. When one action is completed, the next unit takes up the next step

and so on. And all of this happens out of sight — you don't see the inner workings,

but you see the results.

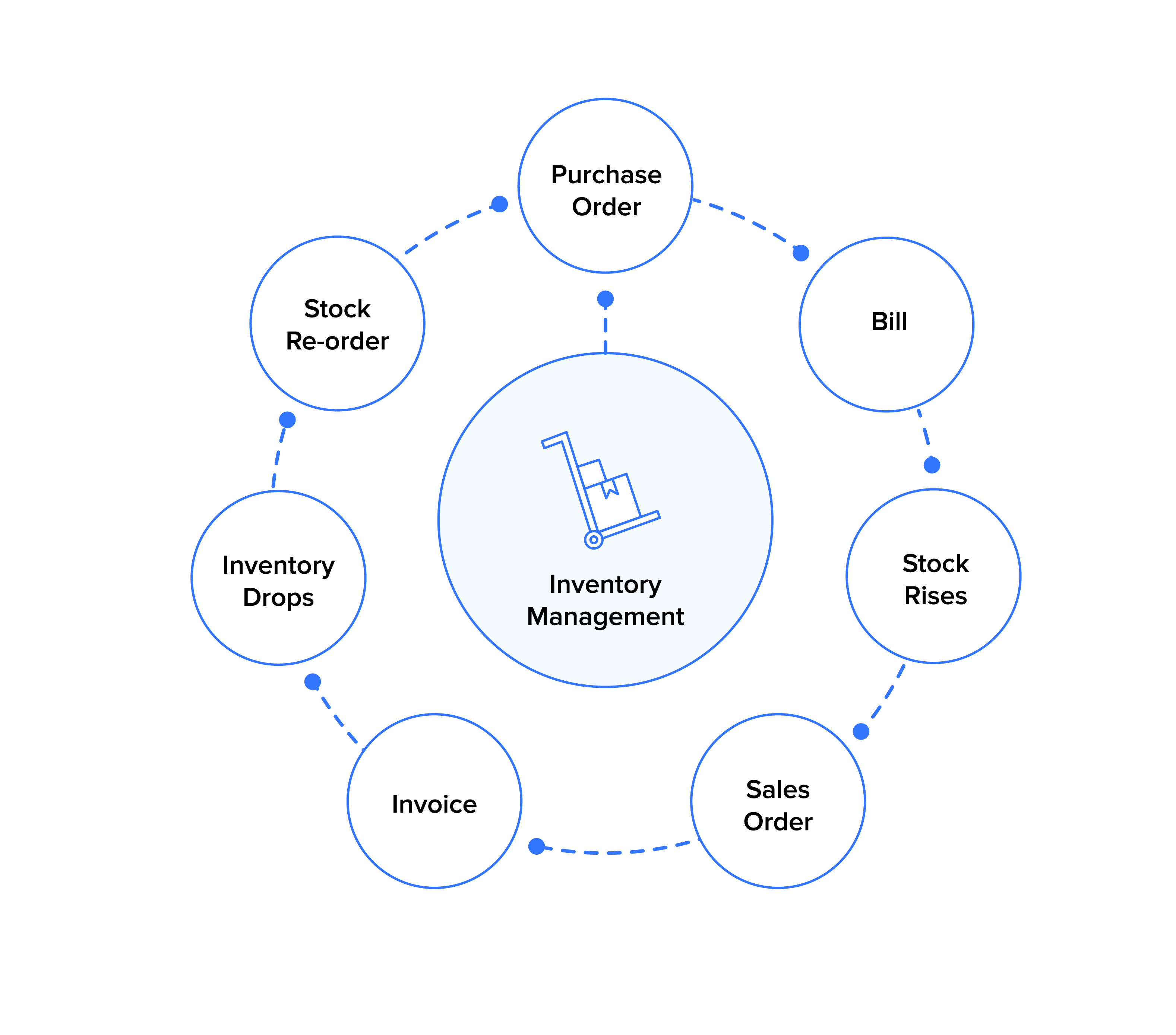

For an organization, inventory management sets up the processes that lead to closing

a deal or making a sale. Just like in an engine, the process in an organization mostly

runs behind the scenes. It usually involves tasks like order management, warehousing,

packaging, and shipment. When you receive an order from your customer, order

management takes care of preparing a sales order and invoice. After the order

confirmation, the warehouse management process will identify the location of the

stock and send it to your store. Then, just like the wheels, the packaging and

shipment process sets the item in motion. It ensures that the item gets packed,

dispatched, and delivered to the customer, on time and safely. Inventory management

enables each component in this process to perform its step and contribute to reaching the desired end.

-

To understand order management let's take a look at these scenarios.

Imagine a customer walks into a bouquet store, picks up his own choice of bouquet, proceeds to the checkout counter, makes

the payment, and exits the shop. This is an example of simple day-to-day transaction that every store owner experiences.

Now, let's take out each step of this process individually and find out how inventory management can play an important role.

-

Product selection

At this stage, inventory management comes into play when you need to identify, and keep track of the availability of the

item that has been bought by the customer. By identification, we are referring to Stock Keeping Unit (SKU) of the item/s

that the customer has decided to buy from your store. You can consider the factors like Manufacturer code, product code,

item attributes (color, size, gender etc) while deciding on the SKU of an item. It's no rocket science but, at the same

time follow these two guidelines before finalizing the SKU:

-

Use alphanumeric codes

Maintain a combination of letters and numbers as it becomes easy to remember and less confusing.

-

Follow cascading methods

While you determine the SKU of a product follow the cascading method or trickle down approach. Start with the Manufacturer code - Supplier ID - Product ID -

Batch No - Product attribute. Keep this pattern uniform for all products so that it becomes even easier to remember them.

Now, going back to our example, how SKU can help the bouquet shop owner? By keeping a unique SKU for all the different types of bouquet she will always be aware,

Which item is her best seller?

Which item is performing the worst?

How much stock she holds?

List of customers who bought that particular item

How frequently she ordered the item from her supplier?

How long the flowers stay fresh? (Tracking the shelf life)

Maintaining an SKU will become all the more significant if she sells assorted bouquets to her customers. Refer the following table (planned).

In case of such items, commonly known as Composite items, she has to maintain two separate SKUs, one for the item itself and one for its constituents.

In the absence of that, her stock status records will be misleading.

-

Invoicing

Invoicing and inventory management! Sounds tricky, right? Although, we would not be talking about what are the tips you can follow to make your invoicing process more efficient

(download our e-book to know more about it), but we will be sharing some useful inventory management tips which can make your invoicing process even better. Here we start.

-

Barcoding

You can save a lot of time managing invoices if you have an inventory management software that supports barcoding. Barcodes are system generated identification tags which are unique in nature. With bar code,

you can do away with the process of manually entering SKU for each item while adding them into the system, creating sales order, and invoices. This way, the room for committing error also reduces.

After generating an invoice there is always a chance that you might update the wrong SKU which in turn will lead to inventory mismatch.

Generate barcode for your items for free here.

-

Item Description

Although, it is a nice invoicing practice, it is also a good marketing tactic. An invoice is something that you hand over to your customer or send via email when a sale is confirmed.

It is something that will stay with your customer in hard or soft copy or both. When you mention the description of the product that your customer has recently bought, it becomes an

effective tool for brand recall. A good detailed description is direct reflection of the efforts that you are exercising in creating better products.

This practice is more applicable when the item is personalized, custom made, or maybe exotic in nature. With intelligent use of words, a customer can have a very delightful experience

and s/he is more likely to recommend your product to his/her peer or friend.

-

Sales order number

In a business, it is always advisable that you maintain sufficient documents for record keeping, analysis, and sometimes to warrant a claim raised by a customer.

One amongst such documents is, Sales order. A sales order is generated once you receive an order from your customer and it shall be subsequently updated with the invoice number,

package slip number, shipping carrier, etc. It is more of an internal document which act as a database of a particular transaction with a specific customer. This single document can

fetch you a lot of information and come in handy during the following situations-

-

Product return

A customer might not be very happy with the product quality and might want to return the item. Product returns can become quite a mess to handle if you do not have proper records

backing the transaction. Your sales order document can act as a peacemaker. When a customer initiates a request, you can always tally the information to check the authenticity of

the transaction and if such an item was ever shipped from your warehouse or store to that particular customer.

-

Delayed or bad delivery

Most likely, the second most common complaint by customer is, delay in delivery or damage caused to the item during transit. Now, at such cases, you might not be at fault but,

since you are the principal point of contact, you are answerable to the customer. If you update the sales order with the package slip number, shipment carrier, and bill; then you

easily trace the company and get proper justifications.

-

If you own multiple warehouses or you stock the items at a small area in your store, check out some of these inventory management tips which can help you to quickly spot the right item, manage them without hassles, and also to avoid confusions.

But, before you read this, you might want to check out our article on : Five things you need to consider before you choose the warehouse location

-

Organization

Inside a warehouse, you can implement some simple measures to organize items in a way such that it makes day-to-day working easy for you.

By organizing, we mean sorting, categorizing, and placing the items at a location on the basis of the nature of the product, their movement, and relevance.

To give you an example, if you stock items in your warehouse in different aisles, then the items which have a high velocity in sales

should be placed closest to the entry so that, you or any of your employees do not have to walk till the end of the room to collect the item.

-

Safety measures

Be it stocking flammable items away from the regular ones or following some standard safety practices to avoid contingencies, hazard management is the need of the hour for every store owner.

Such risks are nothing short of a holocaust for a business, and not being prepared for it will surely turn it into one, if it occurs. So, start your planning with something simple like,

Stick labels on the aisle or pillars to highlight hazardous or flammable material areas

Install fire hydrants and have a good ventilation system

Make sure your staff wear adequate safety gear

How this is a part of Inventory management? At the beginning, we did mentioned that Inventory management also plays an important role in driving up your profitability.

Culminating losses and unwanted risks are some of the ways of achieving that feat.

-

Install locator systems

Just like barcode scanners make order management a breeze, RFID scanners can be very helpful in warehousing operations. RFID scanners are intelligent devices which are

connected with a network and help you to keep track on the movement of the items in as well as out of the warehouse. All you need to do is, install the smart tags on the

items and the scanners will detect the items even if it is not directly in the line of sight.

-

Audit

With the all the items well organized, safety measures at place, and the right technology, it's time to review your stock status. Although there is no fixed timeline

to conduct an audit, it is advisable that you do it at least once a month. The main advantage of doing that is, in case of mismatch you do not have to go through a long trail

to find out the reason. You can also do the audit in a phased manner that is, taking up certain categories of items or covering only specific areas of warehouse at a time.

-

This is the section where order fulfillment comes into action. Order fulfillment is a process that consists of step that help you to deliver the items at your customer's doorstep in

an efficient and cost-effective manner.It is a lot more important if you run a multi-channel business or you take orders from your customers via phone and then dispatch it for delivery.

Here are some of the inventory management tips that could help to smoothen your order fulfillment process :

-

Packaging tips

-

Packing List

Picking list are like directories (maps) which contains all the information about your product. Pick list facilitates work for your warehouse staff. Normally, a pick list

consists of information like, name of the product, type, description, quantity to pack, location of the item etc.

Depending the magnitude of the orders, the pick list can be prepared and handed over to the warehouse for the collection.

-

Pick and pack Process

It refers to the technique by which you decide to pick the items from your warehouse. It differs from one business to other. Here are few of the ways by which the process is done :

-

Discrete - One at a time

You pick items one at a time and as the orders come by. This time of picking process is mostly seen where the items is handed over to the

customer over the counter. To give you an example, a customer has walked into your store to try out a shoe. But, due to the poor fit, he has

requested for larger pair of shoes. In such cases you might need to send your staff to the warehouse to collect the pair.

-

Batch Collection

Instead of collecting the items one at a time in this process you collect multiple items in your visits. But, before you visit to

collect the items, you collaborate all the orders for a particular SKU, known as batches. This type of practice is mostly

followed by companies who have very limited number of SKU in their inventory. Due to this, they usually receive orders for

these items repetatively. In such cases, following the batch method will prove to be very time saving approach.

-

Wave Picking

Under this technique, a time frame or a scheduling window is fixed for picking up the items from the warehouse.

So, if the time frame is three hours then, during the day the warehouse staff will walk along the floor every three hours to collect

the items for which orders has been placed during that time frame. The sceduling window is decided based on the volume and the frequency of the orders.

-

Zone Selection

A designated person is assigned to a zone in the picking area. Whenever an order is received, the worker will scan through

it and pick all the items that fall in his assigned zone. After he has completed his zone, he will pass it to the worker handling the

next zone and so on. This type of picking method is very suitable for supermarkets or a store selling multiple items ranging from cereals to hardware items.

-

Packaging Materials

The first thing that a customer notices when the item reaches their doorstep is the packaging of the product. The quality of material used,

labelling, design, and the overall aesthetics of the package. With many options available to the customers, businessperson have to put some additional emphasis

on the packaging of their products. A lot of customers weigh upon such factors while deciding to buy a product. So, it is evident that you put some efforts in

deciding the packaging of your product before you ship to your customer.

-

Shipping tips

Choosing the right shipping carrier is not an easy task. There are certain factors to be considered, which when overlooked can cause drastic challenges to your business.

To avoid that, we have compiled a list of few to do's that you should follow before zeroing on the shipping carrier -

-

Service Standards

Undoubtedly, the most important yardstick to measure the efficiency of a shipping carrier company. From the conduct of the staff to the accuracy in the delivery time,

do not miss out on the important pointers while choosing the shipping carrier. To find out about the overall reputation in the market, consult with the other business owners.

-

Shipping Costs

After the first level of examination, the next most important criterion is to decide on the cost of shipping goods. The cost of shipping package will vary based on three main factors :

Weight of the package

Type of packaging

Location of delivery

All of these three factors will vary from one order to other but there is a little bit of homework you can do which can make your shipping operations a lot more effective and easy.

You can create a seperate spreadsheet containing details like, Item name, SKU, Weight, Packaging type, etc. This effort will be very helpful when you sit down to calculate the

shipping cost for the packages. When you know these details, you can just put in the figures quickly and find out the cost.

This will save you a lot time and it will help you in decision making. Here are the links to some of the shipping rate calculators :

- USPS Shipping calculator

- UK Royal mail

- FedEx shipping

Although, this seems easy, sometimes it can be overwhelming. Everytime sitting down and finding out the best rates, will take up a lot of your time.

An inventory management software can be very helpful in such cases. It will serve all the shipping integrations at one place and fetch the real time data.

Also, it makes printing shipping labels easy.

Generate shipping labels for free with this free tool from Zoho Inventory.

-

Post shipment updates

One of the best ways of being connected with your customers and winning their trust is by setting up process which is very transparent and clear.

Till the time the items gets delivered, a customer has an expectation that, her "most awaited package" will arrive right at time without any delay.

What if you keep the customer informed about every movement the package makes after it has been dispatched from your warehouse or store? It will not only cut down customer

queries and complaints but also, it will keep them updated about the whereabouts of the package. But, doing it manually will cost a lot of your time.

Therefore, an integration with shipment tracking solution like, AfterShip can help you to achieve that requirement.

All you have to do is to set up your account, integrate your shipping carrier, and you are good to go.

System:

A set of detailed methods, procedures and routines created to carry out a specific activity, perform a duty, or solve a problem.

Imagine you are driving on the highway and you wish to rev up the engine. When you step on the gas,

the engine automatically responds and the components automatically match up to carry out the operation.

The gears, engine, and wheels all step up to make the change without your intervention.

The components themselves create a system, which is a set of rules for how to manage fluctuations

or changes. With a system, the parts are able to work as a whole to respond to new conditions.

Inventory management acts like a system for your organization. If your organization grows or changes,

your structure and process work together to scale up and adapt. Suppose you set up a store in a

new location to expand your sales. Your inventory management acts as a system to guide your organization

through responding to the change in conditions. Your marketing, warehouse, and sales teams can all step

up to adjust their goals and benchmarks, syncing their efforts through your inventory management strategy.

You don't have to start from scratch. The system shows which alterations to the current settings and

plans are needed to achieve your objective.

With the structure being set and the process laid out, Inventory management helps in solving organizational problems and bringing more efficiency

in the daily operations. Whether it's optimizing or improving the tracking, inventory management has an important role to play. Let's take a

look at what are the problems inventory management helps to solve in growing organizations :

-

This is the most effective solution inventory management offers. Be it collaborating orders from different solution, identifying items,

simplifying warehousing operations, and order fulfillment process; inventory management has an important role to play. It helps to

connect the dots, makes it easy to coordinate operations and process the data which can be further processed for decision-making.

If you run a small or medium sized business, limited resources pose a grave challenge for your business. While you handle the day-to-day

operations, you need to make sure that your are making an optimum use of all the resources and not letting go of any opportunity untapped.

Inventory management does help in such situations.

To give you an example, re-order point is an effective formula to avoid missing sales deals. By calculating the re-order level for

different items, you are well prepared when the stock count reaches a particular level. This simple inventory management tactic, also

helps in keeping the warehouse activities in check. By following a simple rule for re-ordering items from your vendor, your warehouse

staff is always aware when is the next consignment expected.

-

With the efforts being put and money spent in a business, it is imperative for any business person to keep an eye on the movement

of the items. An item in your inventory has a quite a bit of journey from the moment it enters your store till it has been dispatched

or handed over to the customer. But, when the volume of orders increase and also the range of products, it becomes quite a struggle

to keep an eye on every movement. Identifying an SKU for items is the best possible way of solving this problem. You can go a step

further and track each item with Serial number tracking or track the expiry of each batch with batch tracking feature. But, this

can be done only after you have identified an SKU for the item.

To learn more about Batch and Serial number tracking you can refer to these links -

- What is Batch tracking?

- What is serial number tracking?

-

Maintaining accurate information is a need for every business, no matter if it's big or small. A lot of organizations usually face this problem wherein their data

is not synchronized and when they decide to process it for further decision making, they couldn't make the head and tail of it. What many companies fail to

fathom is that, the most important aspect of having accurate information is record keeping. The data needs to be stored at every process and it has to be

consistent so that it is relevant to everyone. Inventory management helps in maintaining consistency and accuracy in the data which can be further processed

for planning activities. The sales order number, the SKU of an item, the package slip number, etc. all of these data gets captured at every step if you practice

inventory management. And, since the documentation takes place along with the process and in a step-by-step manner, it is more reliable in nature.

Inventory Control

Inventory Control Warehouse Management

Warehouse Management Multichannel Selling

Multichannel Selling Order Management

Order Management Order Fulfillment

Order Fulfillment Insightful Reports

Insightful Reports