Challenges in Warehouse Management

Ensuring the smooth operation of your warehouse can be quite daunting, especially if you do not know where your problems are. Identifying and understanding the specific challenges of running your warehouse can help you navigate unforeseen circumstances, scale your business, and maintain an efficient operation.

Let’s discuss some of the common challenges in warehouse management and how to tackle them.

Redundant processes

Redundant processes are time-consuming and laborious. For instance, your warehouse staff may spend a significant time in the picking process. In certain instances, you may come across multiple data entries of the same items at different locations of your warehouse. All these repetitive works can lead to huge fluctuations in productivity and increases excessive spending.

Introducing automation can be an ideal way out in this regard. Barcode technology helps in eliminating manual data entries at multiple touchpoints, leading to a more streamlined and efficient inventory.

Handling demand fluctuations

Fluctuating demand can create huge issues in a warehouse. Too much unsold stock can lead to crowding, spoilage, and cash flow problems, while repeated inventory shortages can erode customer confidence and lead to lost business.

Some fluctuations in demand come from unpredictable external factors—like a financial crisis or even a pandemic—while others are more predictable, like seasonal changes in consumer behavior. Using a WMS that offers effective demand forecasting can help you adapt to fluctuations and reduce their impacts on your warehouse.

Poor layout

A poor layout can hamper almost every warehouse management process, from receiving to shipping. Optimizing your inventory for storage is crucial to cut down unnecessary expenses and labor, but many warehouses are still underutilized with regards to their storage space.

Having a WMS can help in overcoming this challenge by ensuring proper utilization of all of your warehouse spaces.

Product damage

One of the worst things that can happen in a warehouse is items getting damaged during transportation within the warehouse. Product damage mostly occurs during picking and packing of items, and it can hurt an organization’s business and bottom line, especially if the items are expensive or difficult to procure.

To minimize product damage, make sure you’re using sturdy, properly assembled modern racking. Take a look at your picking process, too—are items being moved back and forth more than they need to be? An efficient picking process that saves unnecessary trips will also cut down on opportunities for your products to get damaged.

Environmental impacts

Amid all these challenges in your warehouse, you also need to take into account the impact of your warehouse on the environment in the long run. Are you relying on renewable resources or non-renewable ones? Consider the impacts of waste such as packing items and the electricity you use for lighting and appliances.

Ensure that your waste is disposed of properly and that items are recycled and reused where possible. Deciding not to engage in sales of hazardous items can also be a positive step towards eco-friendliness.

Budget constraints

Struggling with the budget is the most common hurdle for small and medium businesses. Many businesses get their warehouse budgeting wrong, not because they need to spend more money on it, but because they need to control costs better. Inefficient staffing and poor use of space can be extremely costly.

Improving worker productivity and making the best use of warehouse space can be a large undertaking, but it offers a substantial ROI for businesses.

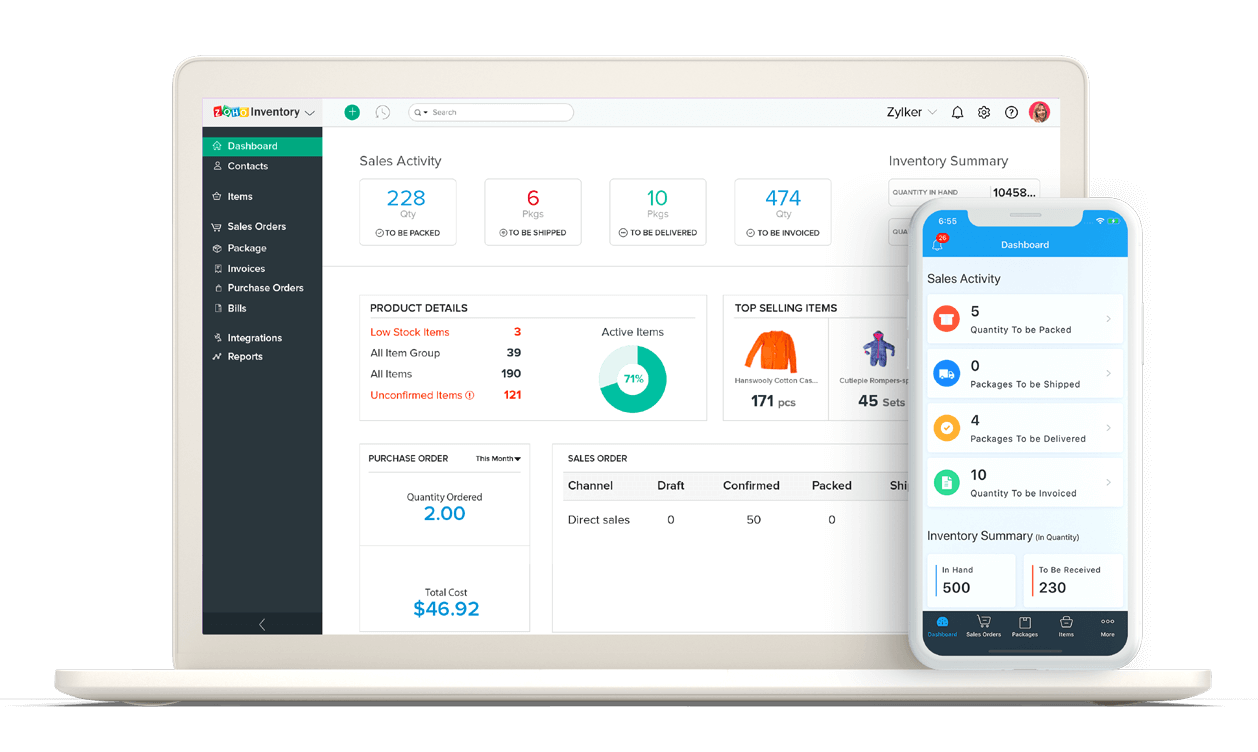

A warehouse management system is the key to tackling most if not all of these challenges. By acting as a smart nerve center of your warehouse, your WMS can help you optimize your space, prepare for demand fluctuations, protect your stock from damage, minimize your environmental footprint, and improve your bottom line. It’s a powerful tool for getting your warehouse operations under control.

Read more: Common warehouse management problems and solutions

Inventory Control

Inventory Control Warehouse Management

Warehouse Management Multichannel Selling

Multichannel Selling Order Management

Order Management Order Fulfillment

Order Fulfillment Insightful Reports

Insightful Reports