- HOME

- Know Your Tech

- Top process improvement methodologies for businesses

Top process improvement methodologies for businesses

- Last Updated : December 1, 2025

- 545 Views

- 11 Min Read

Are your teams constantly chasing deadlines, fixing the same mistakes, or dealing with slow, clunky workflows? If things are always behind schedule or falling through the cracks, it’s a clear sign your processes need a rethink. These inefficiencies can quietly drain productivity, frustrate employees, and impact customer experience.

Highlights

Business process improvement methodologies help organize workflows and enhance quality by focusing on incremental or large-scale changes.

Selecting the right methodology depends on your business goals, team readiness, available tools, and industry needs.

Common challenges include resistance to change and a lack of clear measurement. However, these can be mitigated through strong leadership and clear communication.

Continuous iteration and documentation of outcomes ensure long-term success and sustained improvement.

Fortunately, there is a practical way forward. Business process improvement (BPI) methodologies offer a structured approach to spotting what’s broken, fixing it, and building more efficient systems that support long-term growth.

This blog post explores the top process improvement methodologies, including six sigma, kaizen, SIPOC, and lean. These can help simplify your operations, reduce costly errors, and keep your business competitive in 2025 and beyond.

What is a business process improvement methodology?

A business process improvement methodology is a structured approach to finding and fixing inefficiencies in how your business operates. It gives your team a repeatable framework for identifying problems, testing solutions, and measuring results, ensuring changes actually deliver value.

Studies show that inefficient processes cost businesses significant revenue each year, with companies losing up to $1.3 million annually. That’s why it is necessary to create a framework for continuous improvement, where your team always has the tools and processes to grow.

What matters is that it aligns with your business objectives. This ensures continuous success and long-term benefits for your business. But what are those?

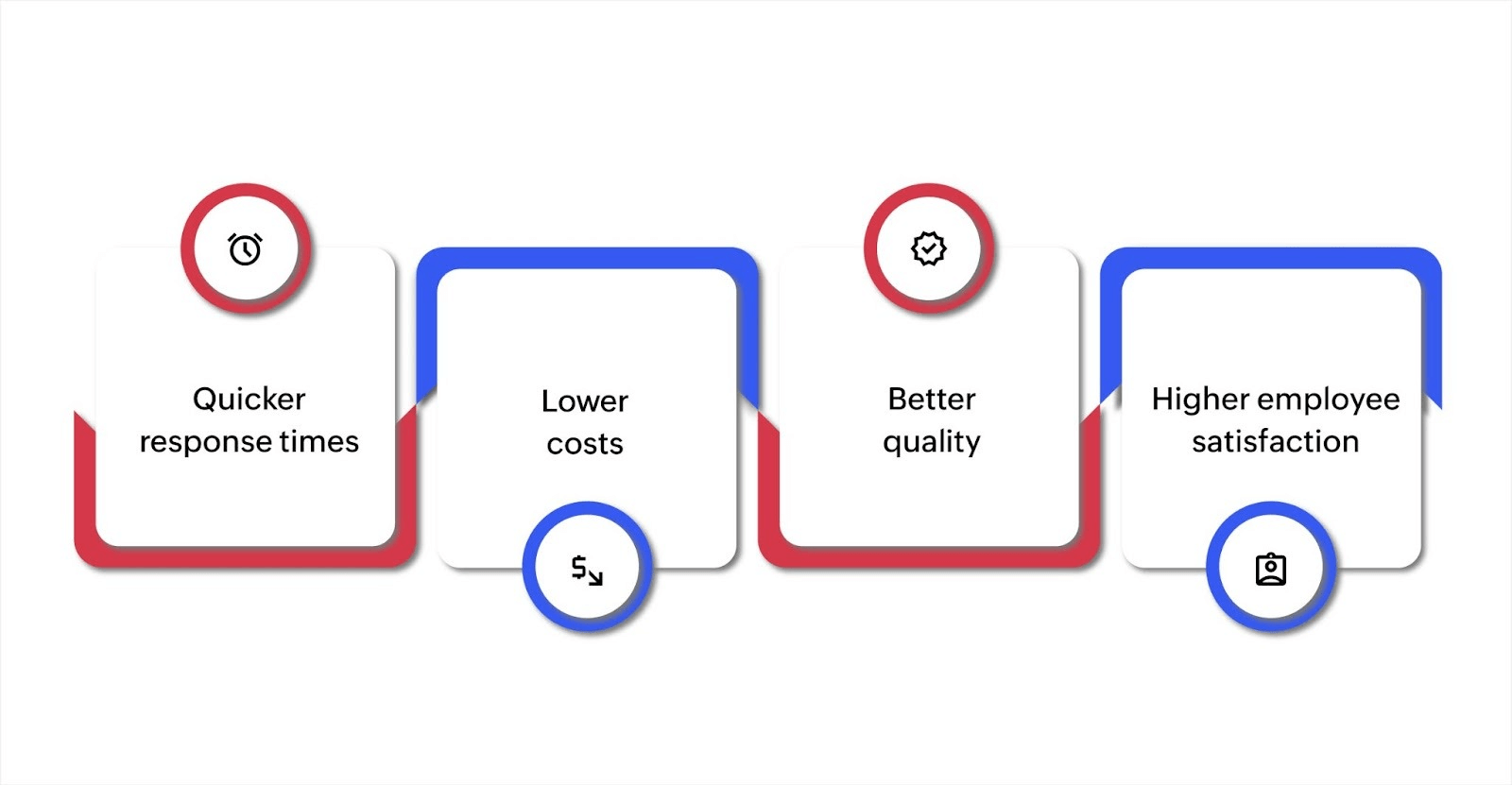

Benefits of process improvement

Process improvement helps you go beyond quick fixes. It allows you to cut down delays without overhauling everything at once. When you improve how your team works, here's what you can expect:

Quicker response times

When workflows are optimized, teams can move faster and more effectively, ensuring that tasks are completed with fewer hiccups. This improves the overall flow of work and accelerates turnaround times.

Lower costs

Every mistake or inefficiency costs your business. From reworking a task to fixing a miscommunication, errors add up. Business process improvement helps reduce these costly errors.

Better quality

When processes run smoothly, quality improves across the board. Organized systems mean your customers receive the quality they expect, and your business gains a stronger reputation.

Higher employee satisfaction

Clear processes make it easier for employees to know what’s expected of them. This reduces confusion, increases productivity, and contributes to a more engaged workforce.

Once you start seeing the results, the next question comes to your mind. That is, how do you consistently achieve them? That’s where process improvement methodologies come in. A few tested, structured ways to redesign how work gets done.

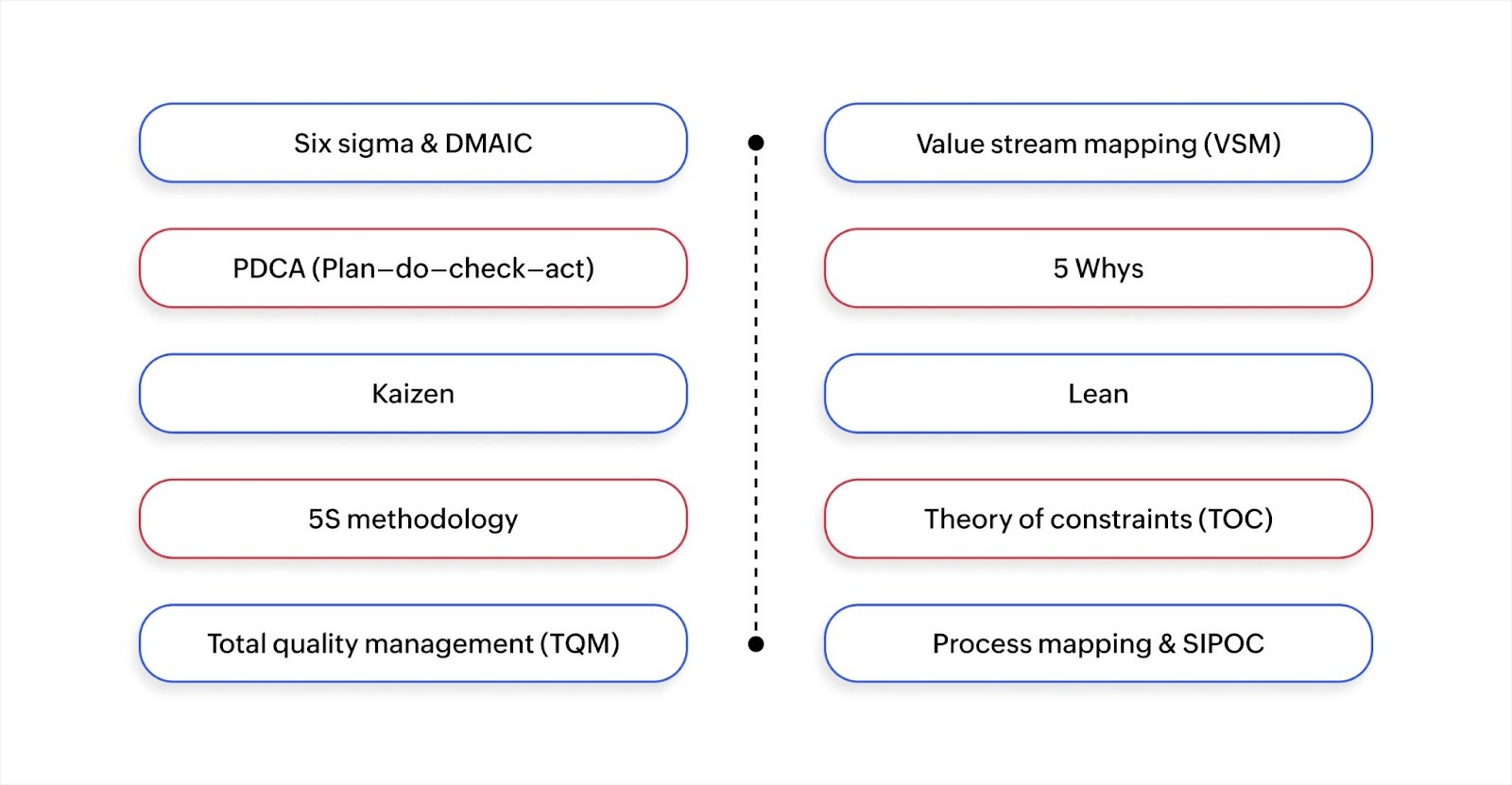

The ten business process improvement methodologies

Selecting the right business process improvement methodology is crucial. Each methodology offers unique tools and techniques suited to different business needs. Let’s take a detailed look at the most popular methodologies that can help drive real change in your organization.

1. Six sigma and DMAIC

Six sigma is a data-driven approach focused on reducing defects and variation within processes. Its goal is to improve process quality by identifying and eliminating the causes of errors. The key tool within Six sigma is DMAIC, which stands for:

Define: Identify the problem or opportunity for improvement.

Measure: Collect data to understand how the current process performs.

Analyze: Look for root causes of issues.

Improve: Implement changes to fix the root causes.

Control: Set up measures to ensure the changes remain effective.

Six sigma is ideal for businesses that want to improve quality and eliminate waste by reducing defects and errors. This method uses statistical tools, such as control charts and hypothesis testing. In this way, it becomes a highly effective methodology for quality-driven industries like manufacturing, healthcare, and finance.

2. PDCA (Plan–do–check–act)

The PDCA cycle is a simple, iterative method for continuous improvement. It’s particularly helpful if you want to make gradual, incremental changes over time.

Plan: Identify what needs improvement and plan changes.

Do: Implement the changes on a small scale.

Check: Measure the results to see if the changes are working.

Act: Standardize the successful changes and make further improvements.

PDCA is a flexible methodology and is often used in quality management and project management.

3. Kaizen

Kaizen, which means "change for the better" in Japanese, is a methodology focused on continuous, incremental improvement. It emphasizes small, frequent improvements that build up over time. This approach encourages employees at all levels to contribute ideas for process improvement, making it a very collaborative methodology.

Principle: Kaizen is built on the idea that improvements don't need to be large or costly.

Tools used: Suggestion boards, daily standups, and visual management tools are common in Kaizen implementations. These tools help gather ideas from employees and monitor progress continuously.

It is particularly effective in manufacturing plants, service industries, and small-to-medium businesses focused on quality and efficiency.

4. 5S methodology

The 5S methodology focuses on improving workplace organization and efficiency. The name comes from five Japanese words: seiri (sort), seiton (set in order), seiso (shine), seiketsu (standardize), and shitsuke (sustain). The goal is to create a clean, organized, and productive environment by focusing on the following steps:

Sort: Remove unnecessary items from the workspace.

Set in order: Arrange tools and materials for easy access.

Shine: Regularly clean the workplace to maintain efficiency.

Standardize: Set standards for processes and organization.

Sustain: Make the 5S practices part of the daily routine.

The 5S methodology can help reduce waste, enhance productivity, and create a safer, more organized workplace. It’s often used in manufacturing environments. However, it is applicable across many industries, particularly where physical workspaces are integral to the business.

5. Total quality management (TQM)

TQM is a comprehensive approach to improving quality across all areas of an organization. TQM aims to fix a company-wide culture of quality, where every employee is responsible for maintaining high standards. It is a long-term strategy focused on customer satisfaction, continuous improvement, and meeting quality standards.

Tools used

Fishbone diagrams to identify root causes of problems

Pareto analysis to identify the most significant causes of issues

Quality audits to ensure adherence to quality standards

Focus: TQM focuses on creating a culture that strives for improvement in every department.

TQM is often used in sectors where maintaining consistent quality is critical, such as healthcare, manufacturing, and service industries. What sets TQM apart from other methodologies is its holistic approach. It integrates every aspect of the business, from leadership to the production floor.

6. Value stream mapping (VSM)

This method is used to analyze the flow of materials and information required to bring a product or service to a customer. It helps businesses identify value-added and non-value-added activities within a process.

What it does: VSM allows you to visually map the entire process flow, from the initial stage to the final delivery. It highlights areas where waste occurs, hurdles that slow down the process, and inefficiencies that reduce value.

How it works: The map typically includes key elements like process steps, information flow, wait times, and inventory levels. With this map in hand, businesses can pinpoint the most critical areas needing improvement.

Benefits: It can drastically shorten lead times, reduce operational costs, and improve overall process efficiency.

It is particularly beneficial in manufacturing and supply chain management. For any business that involves multiple steps to deliver a product or service, VSM is an ideal solution.

7. 5 Whys

The 5 Whys is a simple yet effective problem-solving technique. It helps businesses identify the root cause of an issue by repeatedly asking "why". This process continues until the underlying cause is uncovered.

How it works: Start by identifying the problem, then ask "Why?" to get to the root cause. After each answer, ask "Why?" again, repeating the process until the fundamental cause is revealed. This method typically involves asking five "whys," but you may need fewer or more depending on the situation.

Benefits: The beauty of the 5 Whys lies in its simplicity. It helps teams dig deeper into problems and avoid addressing only symptoms. In this way, businesses can implement more effective solutions that prevent future issues.

This technique is particularly useful for troubleshooting and quality improvement initiatives. It’s often used in manufacturing, customer service, and operational processes.

8. Lean

Lean focuses on eliminating waste and improving the flow of processes. It helps businesses become more efficient by eliminating activities that don’t add value. Lean’s main tools include value stream mapping and the 5 Whys, which help identify and resolve inefficiencies in processes.

When combined with six sigma, lean six sigma becomes even more powerful. Lean focuses on speed, while six sigma focuses on quality. Together, they provide a comprehensive approach to improving both the speed and accuracy of processes.

This methodology works well for businesses looking to increase efficiency and reduce costs. It’s especially useful for industries like manufacturing, logistics, and service-based companies.

9. Theory of constraints (TOC)

The Theory of constraints (TOC) focuses on identifying and addressing the most significant limitations or hurdles in a process. The premise is simple. Steps in TOC:

Identify the constraint: Pinpoint the bottleneck in the process, whether it's a specific task, resource, or part of the workflow.

Exploit the constraint: Make the most of the constraint without making major investments.

Subordinate other processes: Align the rest of the system to support the constraint.

Elevate the constraint: Look for ways to reduce or eliminate the constraint.

Repeat: Once a constraint is resolved, identify the next one and continue improving.

TOC is ideal for businesses with complex systems, such as those in manufacturing, logistics, and supply chain operations. It's especially beneficial in environments where time-to-market, resource availability, and throughput are critical.

However, this approach requires close monitoring and continuous identification of new constraints as improvements are made.

10. Process mapping and SIPOC

Process mapping is a visual representation of a process. SIPOC, which stands for suppliers, inputs, process, outputs, and customers, is a high-level process mapping tool. It's often used at the beginning of process improvement projects to give an overview of how a process works.

Process mapping: Visualizes each step in a workflow, helping to identify inefficiencies, redundant tasks, or gaps.

SIPOC: A tool that outlines the major components of a process, helping to understand key interactions and areas of improvement at a glance.

These tools are ideal for businesses seeking a comprehensive understanding of their processes. Their end goal should be drilling down into specific areas for improvement.

If you’re exploring ways to bring order to disconnected processes and boost operational efficiency, take a look at Zoho Creator’s low‑code business process management platform — it makes designing custom workflows fast and flexible. See how it works in real time or try building something yourself with its visual drag‑and‑drop tools.

Knowing the right methodology is like owning a toolkit. However, tools don’t build anything on their own. To see real results, you need to choose the right one, know when to use it, and commit to the process. That’s where implementation makes all the difference.

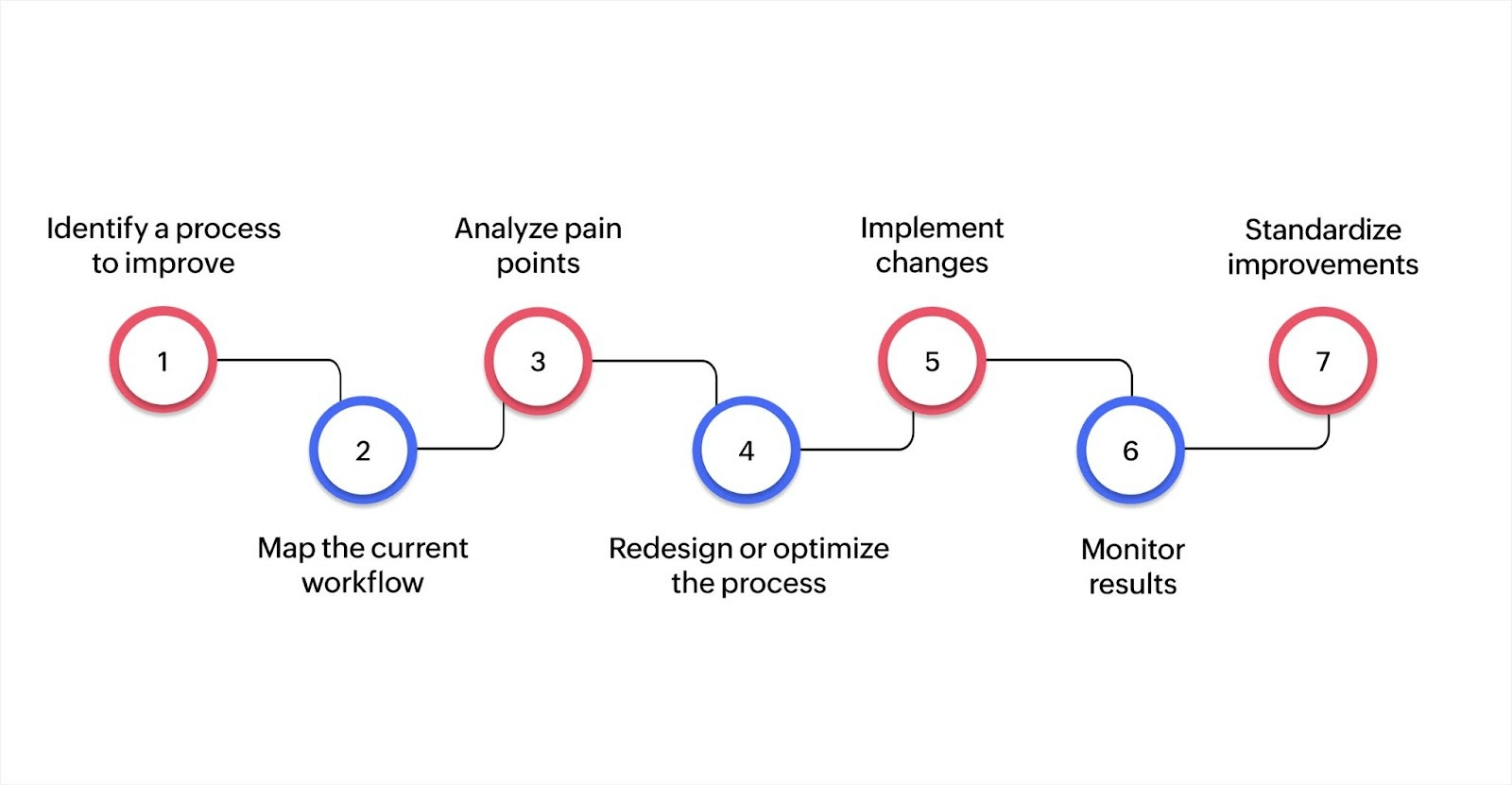

Process improvement lifecycle

When it comes to improving processes, having a clear approach is crucial. A well-defined lifecycle helps businesses stay focused on the end goal and ensures that changes are sustainable. Here’s a breakdown of the essential steps involved in the business process improvement methodology:

Step 1: Identify a process to improve

The first step is to pinpoint which processes are underperforming. This could be anything from manual workflows that slow down productivity to customer service procedures that need fine-tuning.

Step 2: Map the current workflow

Understanding how things currently operate is key to identifying areas for improvement. Tools like process maps and SIPOC templates can help visualize the flow and identify inefficiencies.

Step 3: Analyze pain points

Next, dig into the data and examine where things are breaking down. Use tools like root cause analysis and value stream mapping to uncover the underlying issues that cause delays or errors.

Step 4: Redesign or optimize the process

Once you know where the problems lie, it's time to make changes. This could involve simplifying tasks, removing redundancies, or introducing automation to speed up processes.

Step 5: Implement changes

Put your redesigned process into action. This could be as simple as updating procedures or as advanced as using new software or tools to automate tasks.

Step 6: Monitor results

After implementation, keep a close eye on how the changes are performing. Use dashboards, performance metrics, and feedback loops to track progress and make adjustments as needed.

Step 7: Standardize improvements

Once the process has been optimized, it’s important to standardize the improvements across teams or departments. This ensures that the changes stick and everyone is aligned in following the new, more efficient workflows.

Once you start getting results by following the above steps, it can be rewarding. If you successfully implement the right method, you can expect a 15-25% cost reduction in your business.

However, even with the right plan and tools in place, implementation isn’t the finish line. It's often where the real work begins. From team pushback to unclear ownership, issues can run into roadblocks that slow progress or stall it entirely. To stay ahead of your competitors, you should know how to tackle these challenges.

Challenges in process improvement

No process runs perfectly the first time. So, if you face any hurdle, do not immediately change the method. Instead, try to figure out where teams typically get stuck. Here's a list of common pitfalls you can expect:

Resistance to change

Employees often resist changes, especially if they feel their existing workflows are adequate. To counter this, involve your team early in the process. Educate them on the benefits and provide a platform for their feedback. It’s important that they feel part of the solution rather than just the implementation.

Poor measurement and tracking

Without proper data collection and measurement, it's difficult to assess the effectiveness of the improvements. Tracking key performance indicators (KPIs) will help you monitor progress and adjust strategies as needed.

Lack of clear communication

Miscommunication between teams or unclear messaging about the goals of the project can lead to confusion and a lack of alignment. Establish clear communication channels and ensure that everyone understands the objectives, timelines, and their roles.

With Zoho Creator's intuitive dashboard, you can align with business goals. This feature enables businesses to convert raw data into actionable insights to facilitate effective measurement.

Drive continuous improvement with the right approach

Business process improvement methodology is all about building momentum. The first version of a better workflow won’t be flawless. However, it gives your team a foundation to measure, test, and grow. Each small fix, whether it’s cutting a redundant step or automating a manual task, pushes your operations forward.

The real shift happens when your team treats improvement as an ongoing rhythm, not a one-time project. Start with clear goals, so decisions aren’t based on guesswork. Platforms like Zoho Creator help you create systems/solutions that track what’s working, spot inefficiencies, and adjust without slowing down your teams.

FAQ

What is the best business process improvement methodology for small businesses?

Small businesses often benefit from simpler methodologies like kaizen or PDCA (plan-do-check-act). These approaches allow for gradual improvements without the need for large-scale changes or extensive resources, making them more suitable for smaller teams.

How can data and analytics support process improvement efforts?

Analytics tools help track the effectiveness of process changes over time. Businesses can identify hurdles, measure performance, and make informed decisions using analytical data.

How long does it take to see tangible results from process improvement?

The time it takes to see results can vary depending on the complexity of the process and the methodology used. For some methods, such as kaizen, improvements may be visible within weeks. On the other hand, more structured methodologies like six sigma may take several months to show significant outcomes.

Can process improvement methodologies be applied across different industries?

Yes, most methodologies can be applied across a variety of industries. The specific tools and techniques may vary. However, the core principles of improving efficiency and increasing quality can be adapted to suit the needs of your business.

Ann Elizabeth Sam

Ann Elizabeth SamHey! I'm Ann, and I work as a content writer at Zoho Creator. I'm exploring the SaaS world through various forms of content creation. Outside of work, I love dancing and would give up anything to read a good murder mystery.