- HOME

- Industrial IoT

- How IoT elevates the 7M model of Manufacturing

How IoT elevates the 7M model of Manufacturing

- Last Updated : December 24, 2025

- 120 Views

- 4 Min Read

Every factory has a story. Some stories are filled with breakdowns, delays, and blind spots. Some are about materials being wasted silently, eating into margins. Some are about great teams working without the information they need, simply hoping things go right.

But then there are factories that rewrite their story, factories that sense, think, and act in real time, where quality stays consistent and workflows stay disciplined.

In other words, factories powered by the 7M Model of Manufacturing IoT.

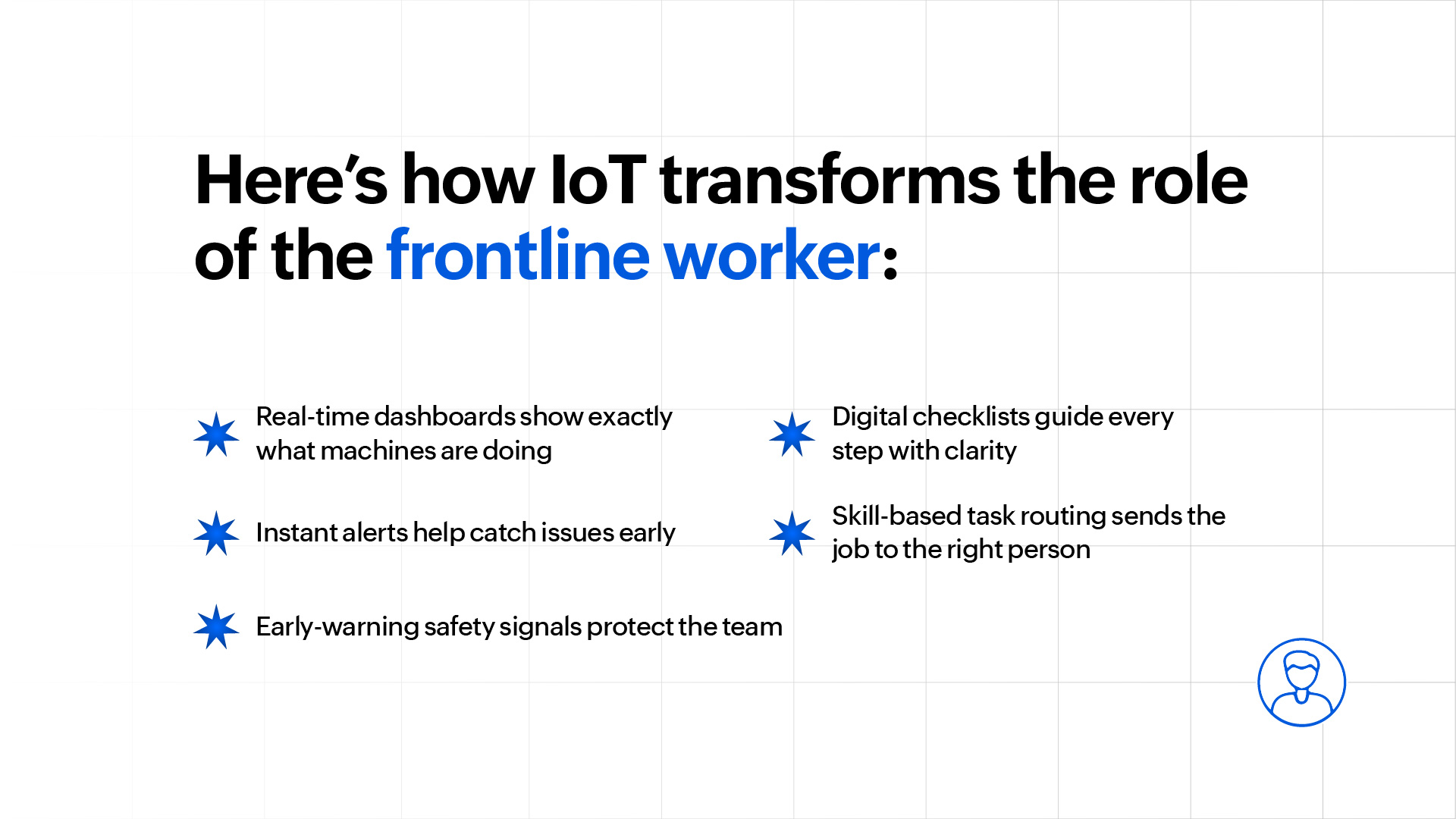

CHAPTER 1: MAN: The Hero Who Needed a Map

Every manufacturing shift begins with people. But for years, machine operators worked with uncertainty. They waited for alarms, reacted only after something went wrong, and relied heavily on memory and paper checklists. Decisions were slow because information was slow.

This is where IoT changes the story.

When workers get real-time data, everything shifts. Machines speak clearly. Issues surface early. Tasks flow to the right person automatically. And safety alerts come before risk turns into danger. Suddenly, with features like predictive maintenance, the operator isn’t just “running the machine” he’s solving problems before they grow.

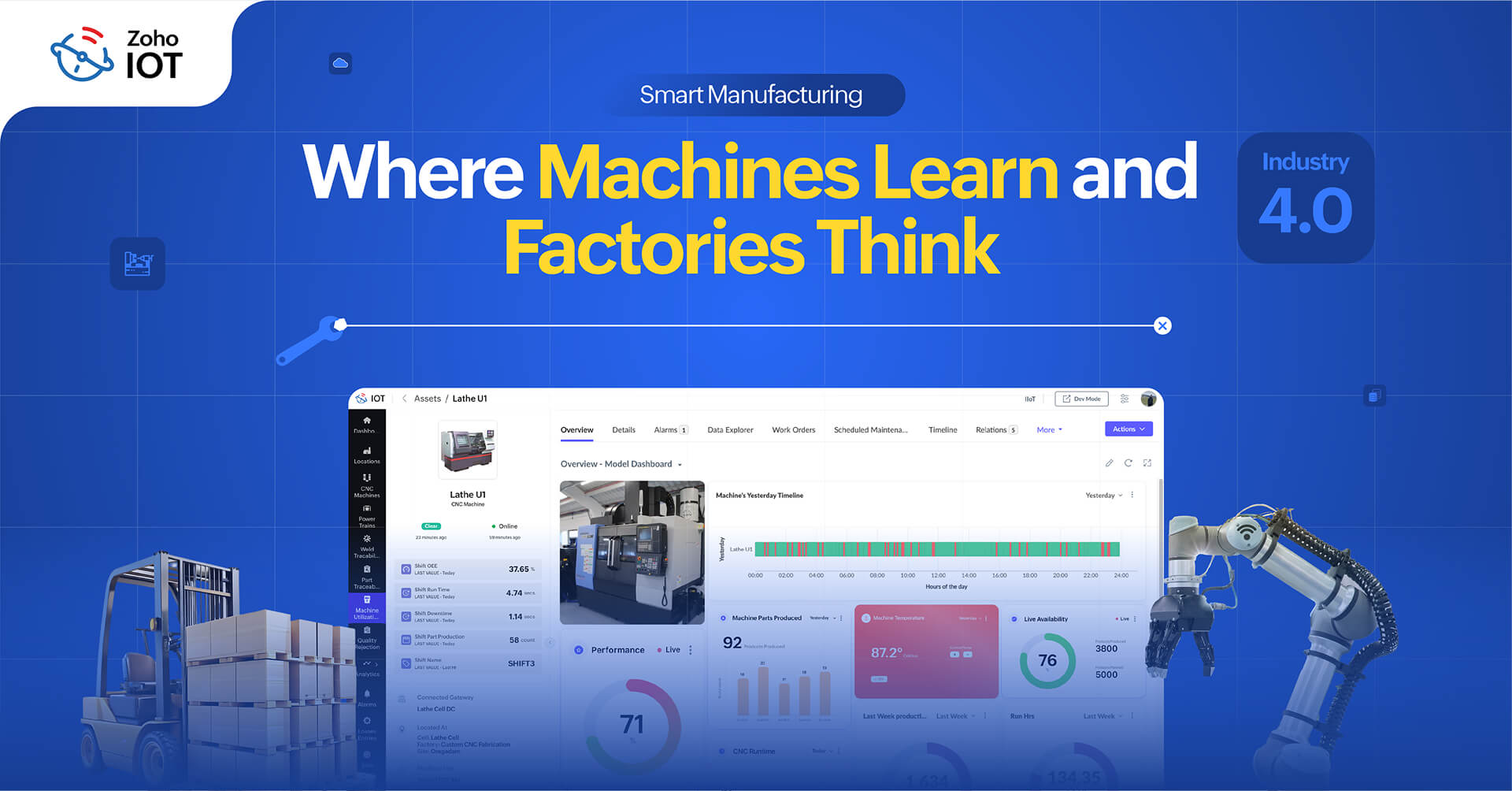

CHAPTER 2: MACHINE: The Giant That Finally Learned to Speak

Machines rarely fail without warning. They whisper first, a little vibration, a bit of heat, a slight change in current. But on old shop floors, no one heard these early signals. Breakdowns felt sudden only because the clues went unnoticed.

With IoT, equipment maintenance is a cakewalk.

The moment sensors start listening, patterns emerge. A CNC begins to drift, a furnace heats unevenly, a compressor vibrates more than usual all tiny signs that once went unseen with IoT asset management. Now, every anomaly detection becomes a clear message. Operators know what’s happening, why it’s happening, and when they need to act leading to fewer surprises, breakdowns, and far more confidence.

CHAPTER 3: MATERIAL: The Silent Cost Driver

Materials react to everything humidity, temperature, how long they wait, and where they’re stored. They spoil quietly, turn into scrap silently, and yet leave a loud impact on cost and quality. In the older factory story, this behavior stayed hidden because no one saw it in real time.

IoT changes that by making material movement, condition, and consumption visible.

When materials are tracked continuously, factories start noticing the patterns that were previously invisible where waste begins, which stages cause variability, and how environmental shifts affect performance. Suddenly, controlling cost and quality becomes a matter of insight, not guesswork.

CHAPTER 4: METHOD: The Discipline That Holds the Factory Together

Methods are the backbone of every factory. But in traditional shop floors, paper-based SOPs get ignored, steps are forgotten, and machines drift from their ideal settings.

Entry IoT, methods become intelligent, guided, and impossible to overlook.

Instead of relying on memory or manuals, the system triggers the right workflow at the exact moment it’s needed. Operators see digital SOPs contextually not as files to search for, but as steps that appear automatically. When time, torque, pressure, or temperature fall out of range, the system flags it instantly. Sensitive processes become stable because recipes stay locked and unchanged.

CHAPTER 5: MEASUREMENT: The Factory’s Superpower

Measurement is the factory’s truth. It brings clarity, exposes patterns, and acts as the nervous system that connects every process. Without measurement, decisions become guesses. With it, decisions become science.

IoT strengthens this backbone by measuring what truly matters continuously, accurately, and without manual effort.

Sensors capture every critical parameter: temperature, torque, vibration, current, flow, pressure and more. Calibration reminders ensure accuracy never slips. KPIs like OEE, MTTR and MTBF update automatically, turning raw numbers into actionable insights. With trend analysis, factories don’t just react, they anticipate.

CHAPTER 6: MANAGEMENT: The Brain That Turns Data Into Decisions

Data alone isn’t power decisions management is where all the other M's come together: Man, Machine, Material, Method, and Measurement. It’s the layer that transforms information into strategy, chaos into coordination, and routine into predictability.

With IoT, management becomes real time.

Production schedules align automatically with machine availability. Escalations move instantly to the right teams. Insights from different departments merge into a single view, helping leaders plan with confidence rather than assumptions. Governance shifts from manual oversight to automated rules, and condition-based triggers generate work orders without waiting for human intervention.

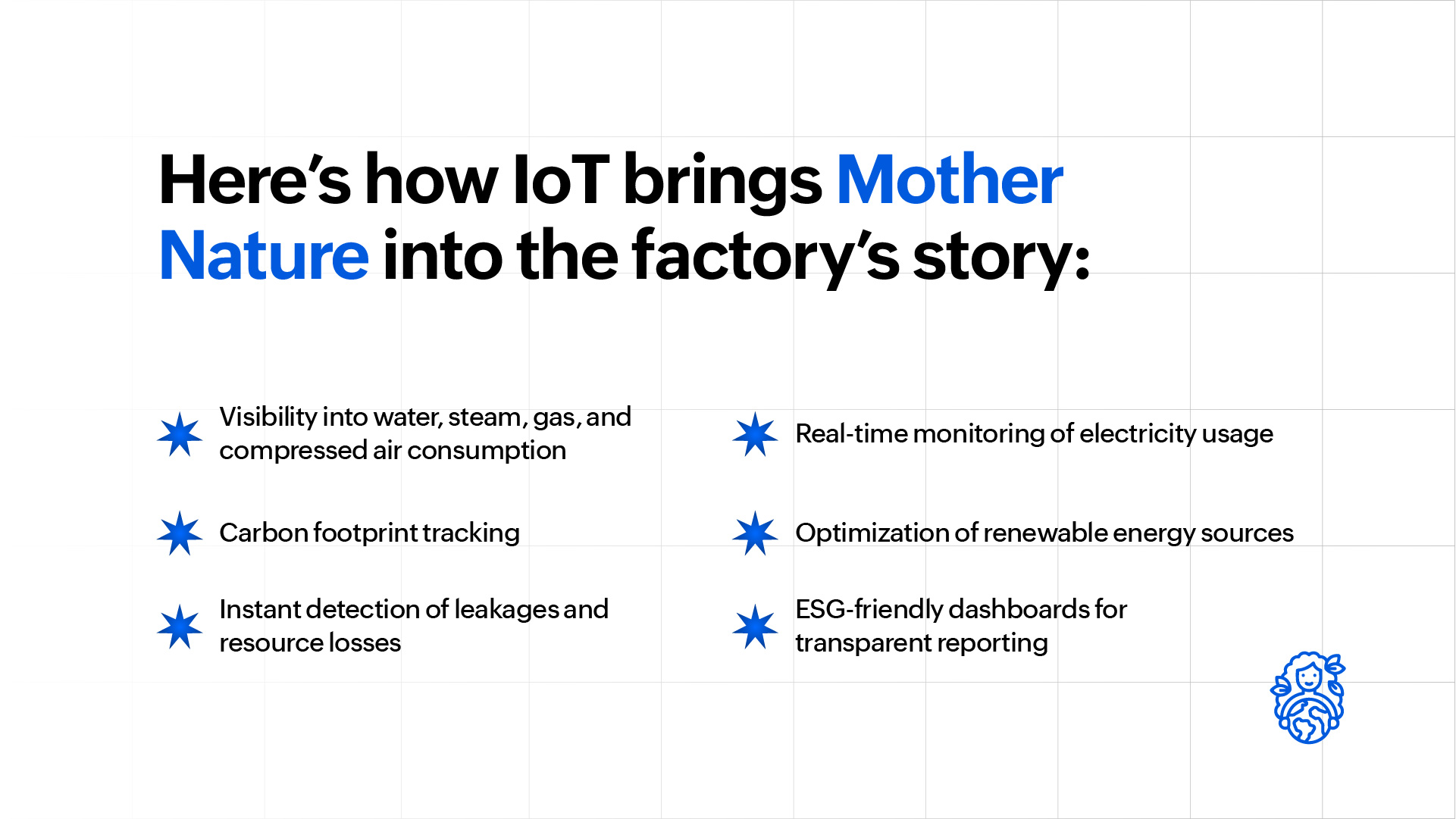

CHAPTER 7: MOTHER NATURE: The Silent Judge of Every Factory

A factory never operates in isolation. It shares air, water, energy, and resources with everything around it. And while humans track productivity and output, Mother nature observes something else entirely waste, emissions, inefficiency, and impact.

With IoT, nature becomes part of the factory’s decision-making.

Energy consumption is monitored in real time. Water, steam, gas, and compressed air usage become visible instead of hidden. Carbon footprint becomes a measurable metric, not an estimation. Losses and leakages surface instantly, helping teams save money while reducing environmental harm. Sustainability shifts from a compliance checkbox to an operational habit.

How Zoho IoT Unifies the 7Ms of Manufacturing

A factory becomes truly intelligent only when all seven pillars, Man, Machine, Material, Method, Measurement, Management, and Mother Nature work in sync.

Zoho IoT acts as the invisible thread that connects them. It listens, learns, and responds across every layer of the shop floor, turning scattered data into meaningful action.

Here’s how Zoho IoT brings all 7Ms together:

- Man reacts faster with real-time insights

- Machine stays reliable through predictive monitoring

- Material stays controlled with complete visibility

- Method stays consistent through digital workflows

- Measurement stays accurate with live sensor data

- Management stays informed through unified dashboards

- Mother Nature stays protected through energy and resource optimization.

The Verdict

Every factory has two stories:

One written by guesswork.

And one written by intelligence.

Choose wisely.

The 7M Manufacturing IoT Model, created by Praveen from Zoho IoT, helps factories choose the smarter story the story where every person, every machine, every material, every method, every measurement, every decision, and every environmental impact moves in complete alignment.

It’s the story of a factory that is no longer passive but alive, aware, and ready for the future.

Talk to the Zoho IoT team and see how the 7M Model can transform your operations end to end.