- HOME

- Industrial IoT

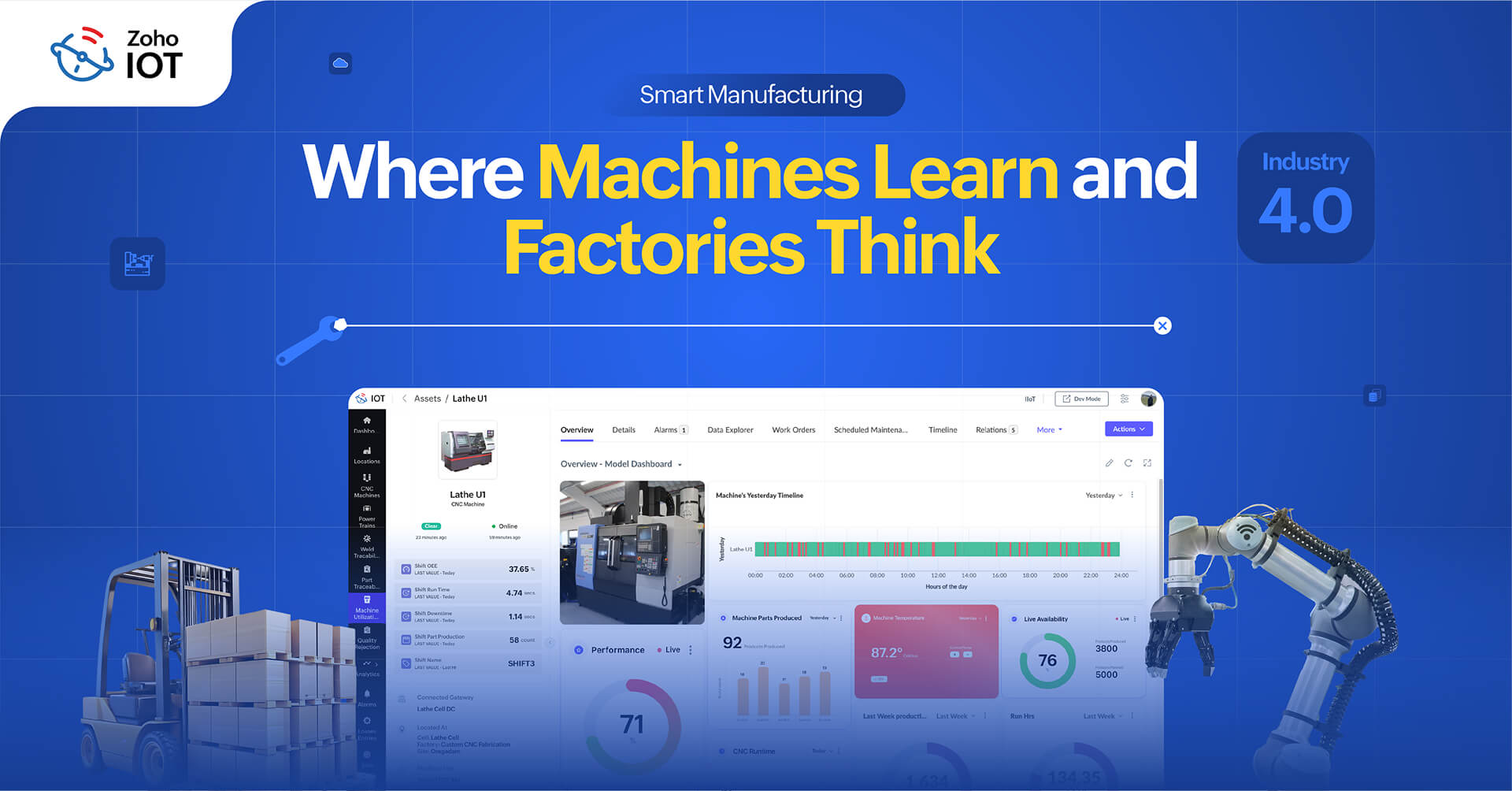

- Industrial Automation & Smart Manufacturing with IIoT

Industrial Automation & Smart Manufacturing with IIoT

- Last Updated : February 16, 2026

- 131 Views

- 5 Min Read

Across factories, energy grids, water networks, and utilities, thousands of machines work silently. Pumps, turbines, mixers, valves, and sensors operate continuously, supported by systems such as SCADA and BMS. These tools show what is happening, but today, monitoring alone is not enough.

- What if a pump could warn you before it failed?

- What if a transformer’s unusual load pattern could trigger preventive action?

- What if production schedules could adjust the moment a machine drifted out of specification?

This is where Industrial IoT steps in.

IIoT does more than collect data. It interprets patterns, predicts issues, and coordinates action across PLCs, SCADA, MES, WMS, BMS, and field assets. It transforms basic supervision into intelligent automation.

Zoho IoT brings this intelligence together by unifying machines, buildings, and enterprise workflows into one reliable and scalable ecosystem.

Foundations of Industrial Automation

Automation across industries builds on a robust stack of technologies that work together to ensure reliable, efficient operations:

- Sensors and industrial instruments capture real-time data from the physical world.

- PLCs, RTUs, controllers, and drives execute control logic at the edge.

- Edge processing enables rapid, local decision-making.

- SCADA provides supervisory control and data acquisition.

- MES and enterprise systems coordinate workflows and production.

- Cloud dashboards offer multi-site visibility and reporting.

- Analytics drive optimization and predictive capabilities.

These components form the backbone of modern industrial systems, from machine-level control to enterprise oversight.

Understanding the Automation Hierarchy

Automation operates at three mutually supportive layers:

- Industrial Automation - Oversees multi-site operations (plants, substations, grids), ensuring safety, reliability, and continuity.

- Factory Automation - Coordinates machines, lines, materials, and workflows within one facility.

- Manufacturing Automation - Executes precise machine-level tasks such as assembly, cutting, filling, and inspection.

This structure links machine actions → plant performance → enterprise outcomes.

Automation Comparison Chart (Manufacturing-Based Analogy)

Feature | Industrial Automation | Factory Automation | Manufacturing Automation |

Simple Analogy | Supply chain control tower | Plant manager | Workstation operator |

Business Analogy | Managing a company across cities | Running all departments in one building | Performing one specialised task |

Scope | Multi-site operations | Entire plant operations | Machine-level processes |

Primary Goal | Reliability & safety | Flow & visibility | Precision & quality |

Key Technologies | SCADA, DCS, telemetry | MES, WMS, AGVs, PLCs | Robots, CNCs, vision systems |

Common Data | Asset health, compliance | OEE, throughput, material flow | Cycle times, sensor & QC data |

Users | OT admins, control engineers | Plant managers, schedulers | Operators, technicians |

Example Activity | Monitoring multiple plants | Coordinating lines & materials | Inspecting or assembling components |

Explore more in our industrial IoT solutions and smart manufacturing pages.

The Factory Floor Toolkit: Essential Technologies for Seamless Operations

Core technologies serve as the building blocks for efficient automation:

Technology | Role (Analogy) | Primary Function | Scope in the Plant |

PLC | The Machine Brain | Controls machines, sensors, actuators, and safety interlocks. | Machine / Cell Level |

MES | The Production Manager | Schedules and manages real-time production, linking ERP and shop floor. | Production Line / Plant Floor |

WMS | The Inventory Conductor | Manages storage, retrieval, and material flow. | Warehouse / Storage Areas |

AGV | The Internal Courier | Transports materials across the facility using guided paths. | Plant-Wide Logistics |

BMS | The Facility Guardian | Manages HVAC, lighting, energy, and building systems. | Entire Facility |

Zoho IoT ensures smooth PLC integration, MES integration, and SCADA integration. See our device connectivity options.

How Zoho IoT Complements and Integrates with These Core Technologies

Zoho IoT acts as the unifying IIoT platform that enhances these essential technologies by connecting them into a single, intelligent ecosystem. It doesn't replace your existing industrial control systems, instead it complements them with cloud-based analytics, real-time monitoring, predictive capabilities, and low-code automation, bridging the gap between operational technology (OT) and information technology (IT).

Key ways of complementing:

- Enhanced Data Flow - Pulls high-frequency data from PLCs and BMS sensors, enriches SCADA oversight, and feeds real-time insights into MES and WMS for better decision-making.

- Predictive Maintenance - Applies analytics to detect anomalies (e.g., machine vibrations via PLC data or energy spikes via BMS), enabling proactive maintenance across the board.

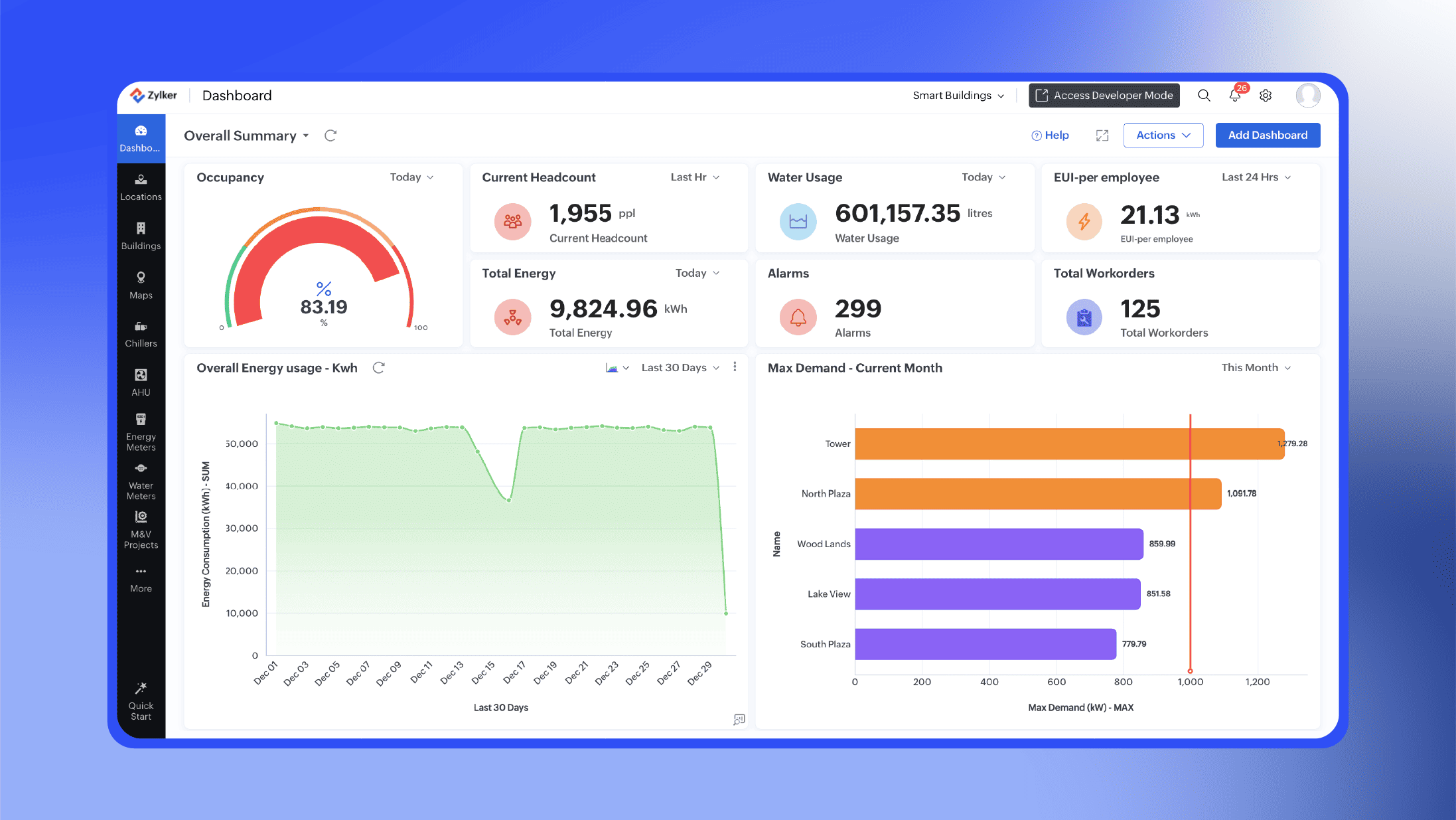

- Unified Visibility - Consolidates dashboards showing PLC status, MES production metrics, WMS inventory levels, AGV routes, and BMS energy usage in one place.

- Automation Workflows - Low-code rules trigger actions, like rerouting AGVs based on WMS stock levels or adjusting HVAC via BMS for energy savings.

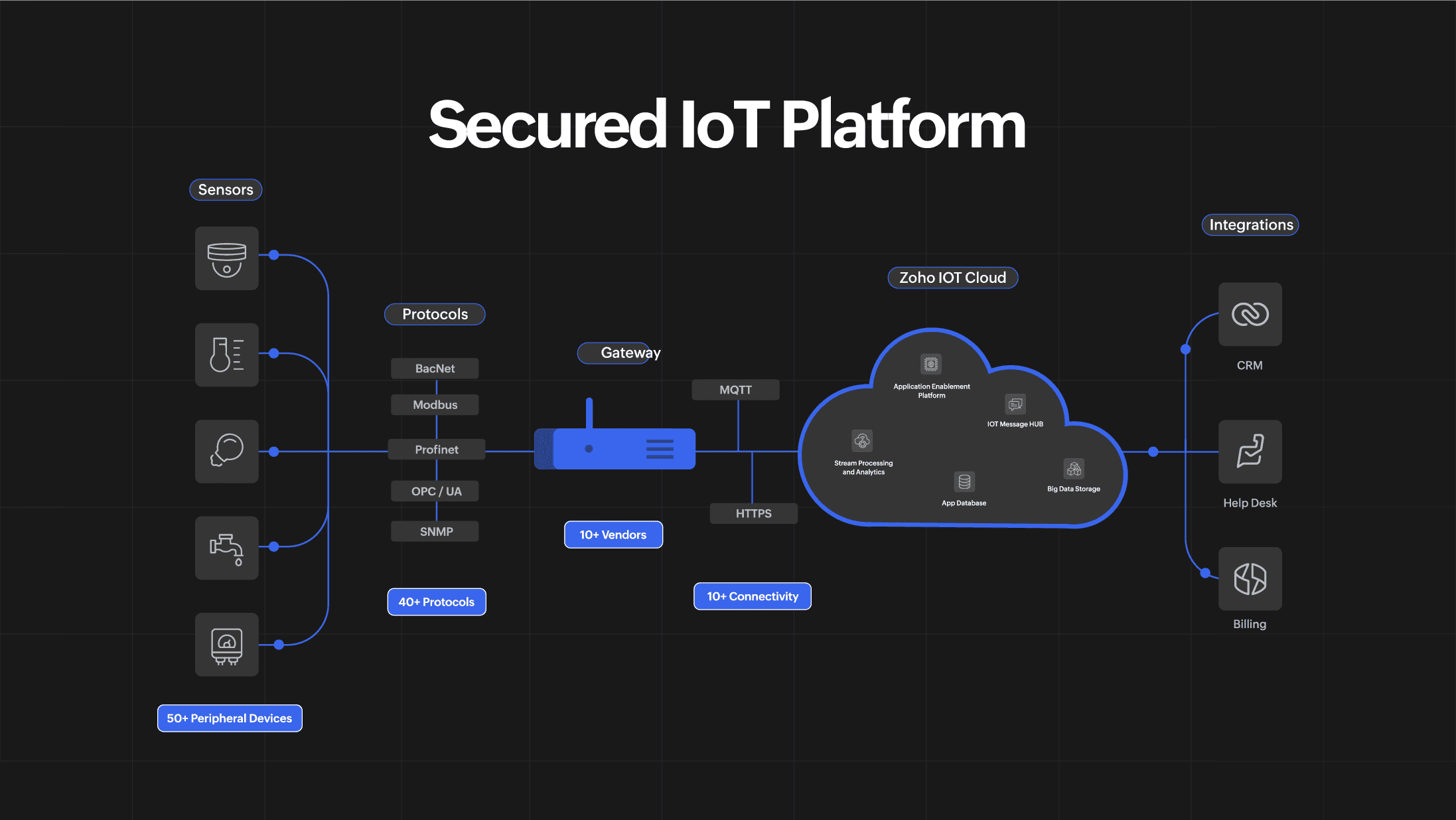

- Scalability - Supports multi-site operations, normalizing data from diverse vendors and protocols (Modbus, OPC-UA, BACnet, etc.).

Simple Integration Examples:

- Manufacturing Use Case: A food processing plant integrates PLCs controlling mixers with Zoho IoT. When a PLC detects rising motor temperature, Zoho IoT alerts the MES to pause production scheduling, notifies maintenance via workflow, and updates WMS to hold related inventory, thereby preventing downtime and waste.

- Energy & Utilities Use Case: A commercial facility or substation integrates BMS for HVAC and lighting control. Zoho IoT analyses BMS data alongside energy meters to predict peak loads, automatically dim lights or adjust temperatures, reducing costs by 15-20% while maintaining comfort.

- Smart buildings Use Case: In a water treatment plant, BMS monitors facility systems while SCADA handles pumps. Zoho IoT unifies them to detect leaks via pressure anomalies, trigger valve adjustments, and generate compliance reports automatically.

By integrating seamlessly with PLCs, MES, WMS, AGVs, BMS, and SCADA, Zoho IoT transforms isolated tools into a cohesive, predictive system which helps drive efficiency in smart manufacturing, energy automation, and utilities automation.

Discover more in our industrial IoT solutions.

How Industrial IoT Strengthens Automation

Industrial IoT connects machines, equipment, and field assets into a unified system, enabling organizations to:

- Monitor equipment and processes in real time.

- Detect irregularities early.

- Reduce downtime with predictive insights.

- Improve product and service quality.

- Strengthen OT/IT security.

- Gain visibility across multiple plants or sites.

- Standardize operations at scale.

Why Industries Are Accelerating Adoption of IIoT and Automation

Industries face downtime risks, rising energy costs, aging equipment, compliance pressure, and fragmented OT/IT systems. IIoT resolves these by:

- Reducing failures through predictive insights

- Increasing visibility across plants and field assets

- Boosting throughput and quality

- Enabling energy efficiency and sustainability

- Connecting distributed systems at scale

Zoho IoT: Seamless Integration Across Industrial Systems

Zoho IoT integrates with existing equipment, no rip-and-replace needed making deployments smooth and scalable.

How Integration Works

- Connect equipment via gateways or native protocols.

- Collect real-time machine and facility data.

- Standardize formats from multiple vendors.

- Analyse using dashboards, alerts, and predictions.

- Act through workflows and automated actions.

- Scale to more plants, grids, or remote sites instantly.

Zoho IoT: Your Unified Platform for Industrial Automation

Zoho IoT bridges OT (PLCs, SCADA) with IT (MES, ERP) for predictive, scalable operations.

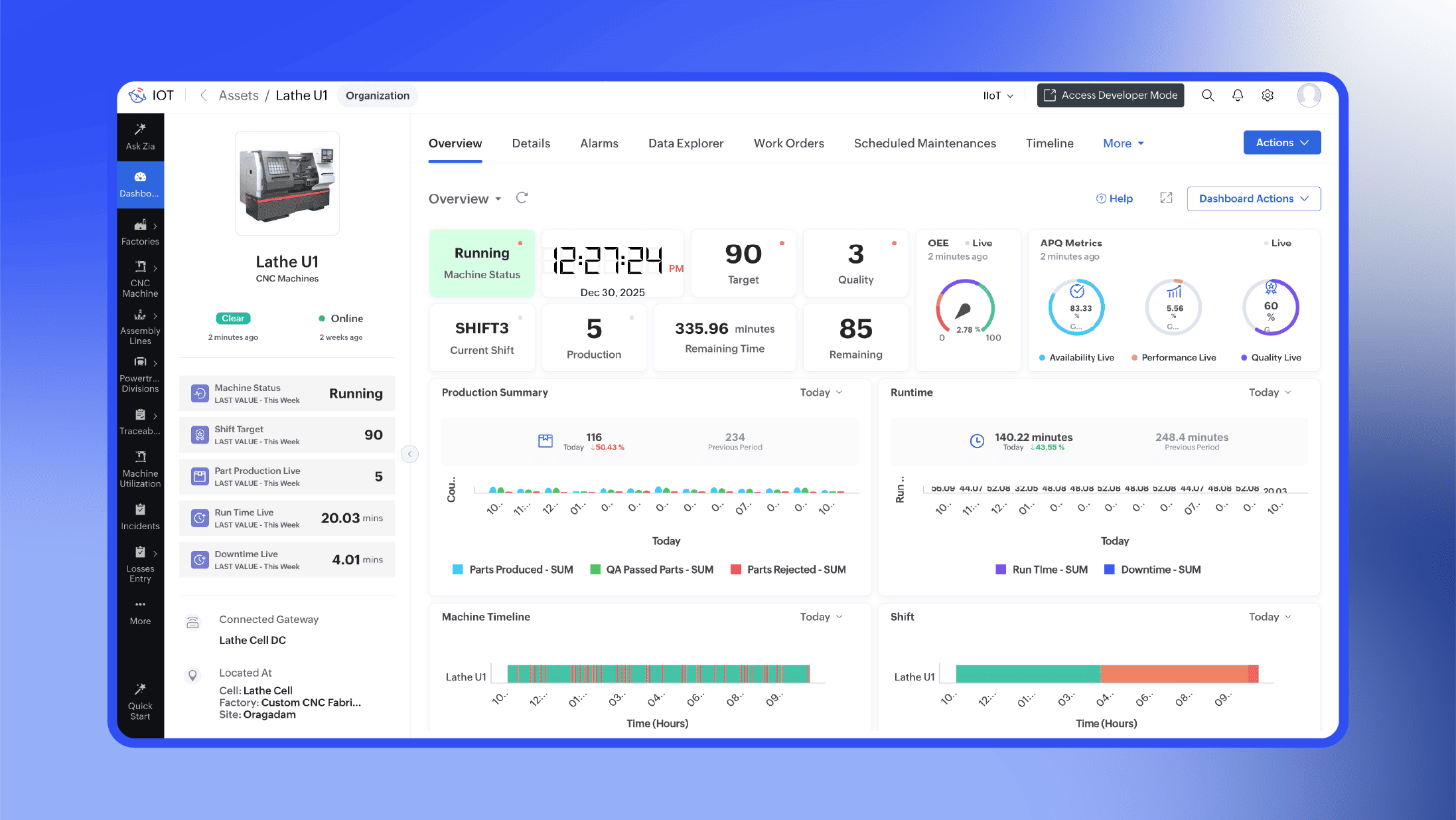

1. Smart Manufacturing & Factory Operations

Zoho IoT provides end-to-end visibility for better decisions.

- Core Capabilities:

- PLC connections for machine data.

- Enhanced SCADA with analytics and detection.

- Real-time MES alignment.

- Instant quality alerts.

- OEE dashboards.

Use Case: Vibration spike → Anomaly detected → Workflow triggered → Failure prevented.

2. Energy Automation: Monitoring Grids, Generation, and Renewables

Unified oversight for distributed assets.

- Core Capabilities:

- Monitor transformers, inverters, turbines.

- Predict failures.

- Track voltage, load, frequency.

- Consolidated renewable dashboards.

3. Utilities Automation: Water, Wastewater, and Distribution

Precise data for reliable service.

- Core Capabilities:

- Monitor pumps, valves, pressure, flow.

- Detect leaks.

- Automate compliance reporting.

- Optimize pumping energy.

- Centralize remote stations.

Common Use Cases Across Manufacturing, Energy, and Utilities

- Machine condition monitoring

- Predictive/preventive maintenance

- Quality checks and alerts

- OEE and production reporting

- Energy consumption insights

- Pump, flow, pressure tracking

- Grid load visibility

- Compliance reporting

- Remote site supervision

- Daily workflow automation

Why Zoho IoT Fits These Industries Perfectly

- Seamless with existing OT systems

- Low-code workflows for easy adoption

- Multi-protocol support

- Easy scaling across locations

- Real-time dashboards

- Predictive analytics to cut downtime

- Built-in OT/IoT security

- Expansion without overhaul

Zoho IoT modernises operations without disrupting what works. View the full features.

Conclusion: Achieve Clarity and Control with Zoho IoT

Industrial automation powered by Zoho IoT turns complexity into predictable efficiency in manufacturing, energy, and utilities. With real-time monitoring, predictive maintenance, and seamless OT/IT integration, you reduce downtime, boost quality, ensure compliance, optimize energy, and manage remote assets effortlessly.

Shift from reactive to proactive and explore how Zoho IoT elevates your industrial IoT strategy today.