- HOME

- Industrial IoT

- How is IIoT transforming the Manufacturing Industry?

How is IIoT transforming the Manufacturing Industry?

- Last Updated : August 21, 2025

- 351 Views

- 6 Min Read

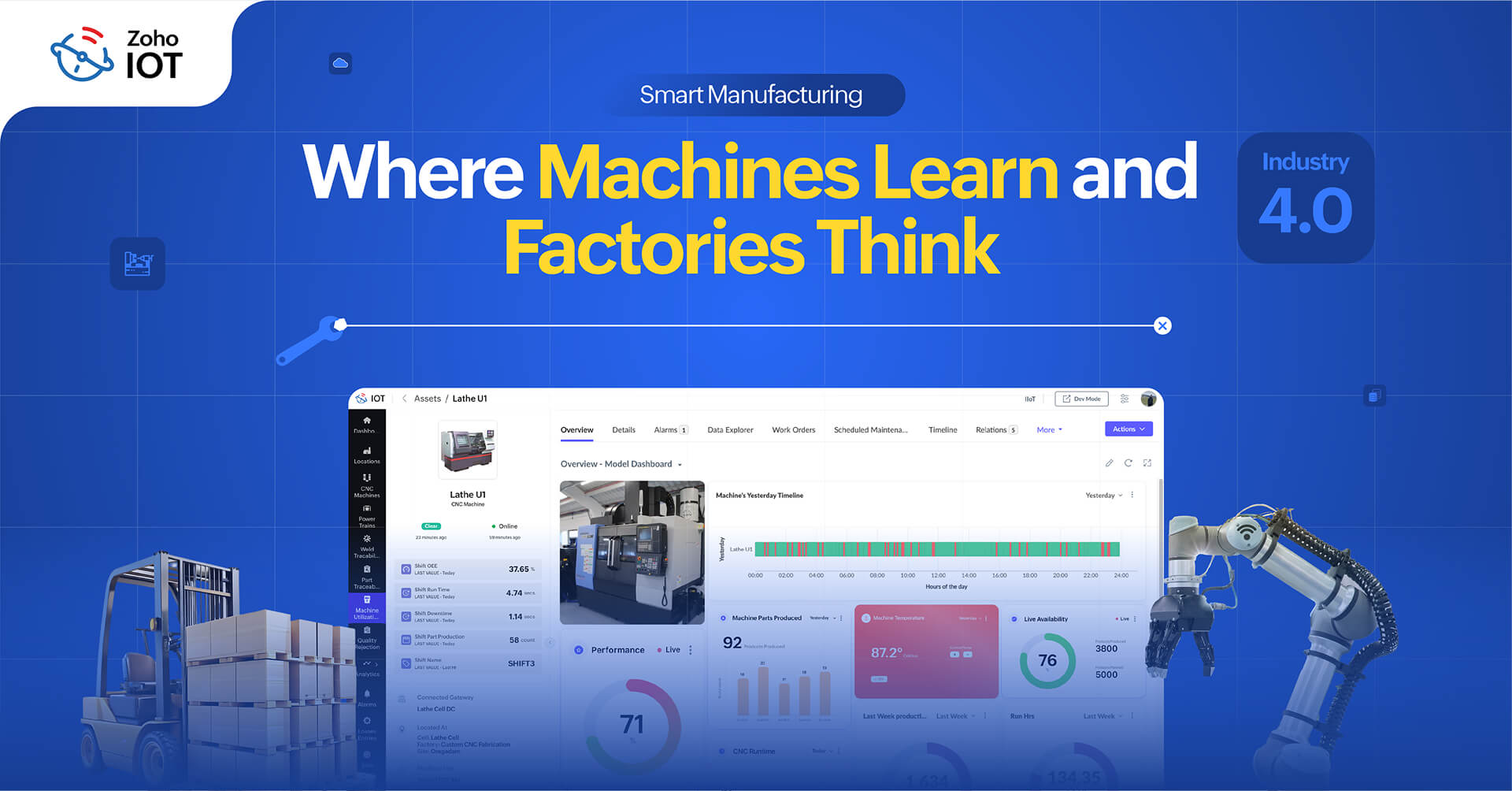

Industrial IoT within just a short span has brought an exceptional disruption in the manufacturing domain while also offering immense hope for its automated future. It is transforming the traditional linear manufacturing supply system into a dynamic, interconnected process that revolutionizes the way products are made and delivered. While technology makes factories more efficient and safer for human operators, it also has an impact on industrial productivity and cost savings. In fact, according to Capgemini, 62% of the industrial manufacturing sector is already using IoT technology in operations, and that number is almost sure to rise in the coming months. That’s why it seems like everyone’s talking about the IIoT right now.

However, not everyone is talking about it the same way.

While technology enthusiasts and analysts often fascinate the technical specifications and capabilities that IIoT has to offer. The implementers or say, the industry experts who look to solve specific problems, they face in an industrial set-up, majorly focuses on how internet-connected sensors can be of use or deployed to rescue from a costly affair.

In this post, we’ll go on & discuss how(s) and why(s) that are driving the adoption of Industrial IoT in manufacturing.

How IIoT proves to be an answer to the manufacturer’s quest to attain efficiency while reducing downtime & costs?

IIoT indeed can increase efficiency and reduce downtime, thus, decreasing the cost. However, the question remains, HOW?

The use of sensors can very well answer it. By deploying a sensor network, managers get real-time insight into their business. When they have sensor data to predict maintenance schedules or automate processes for better production visibility, faster improvement cycles, or even temperature monitoring, their initial problem is solved. They can do much more with the collected sensor data, and that usually happens when the QA team digs in and starts comparing and correlating data points. Getting insights enables manufacturers to make informed decisions, solve problems & thus, the overall cost.

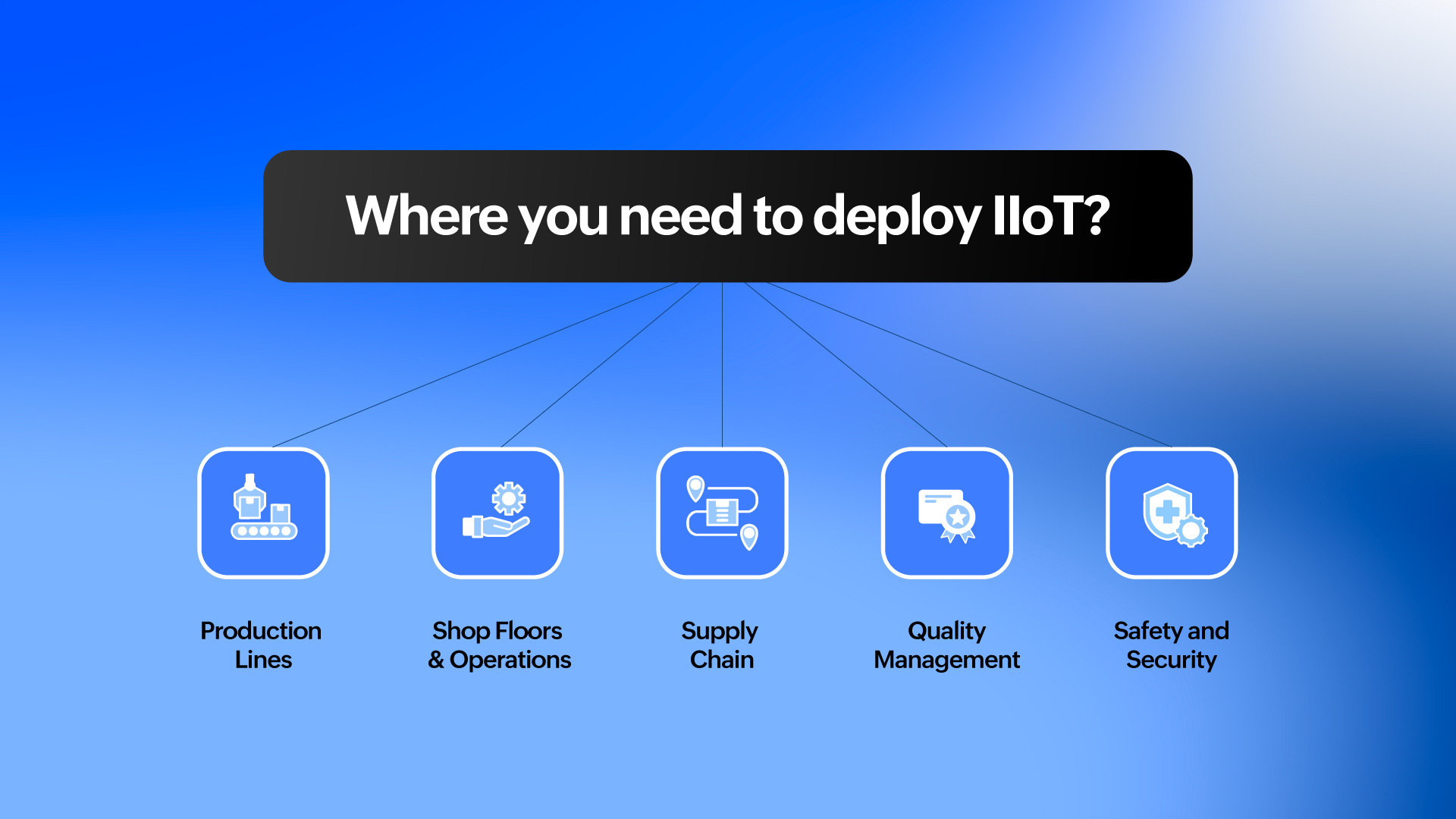

Now, what are those areas where manufacturers need to deploy IIoT sensors?

Production Lines

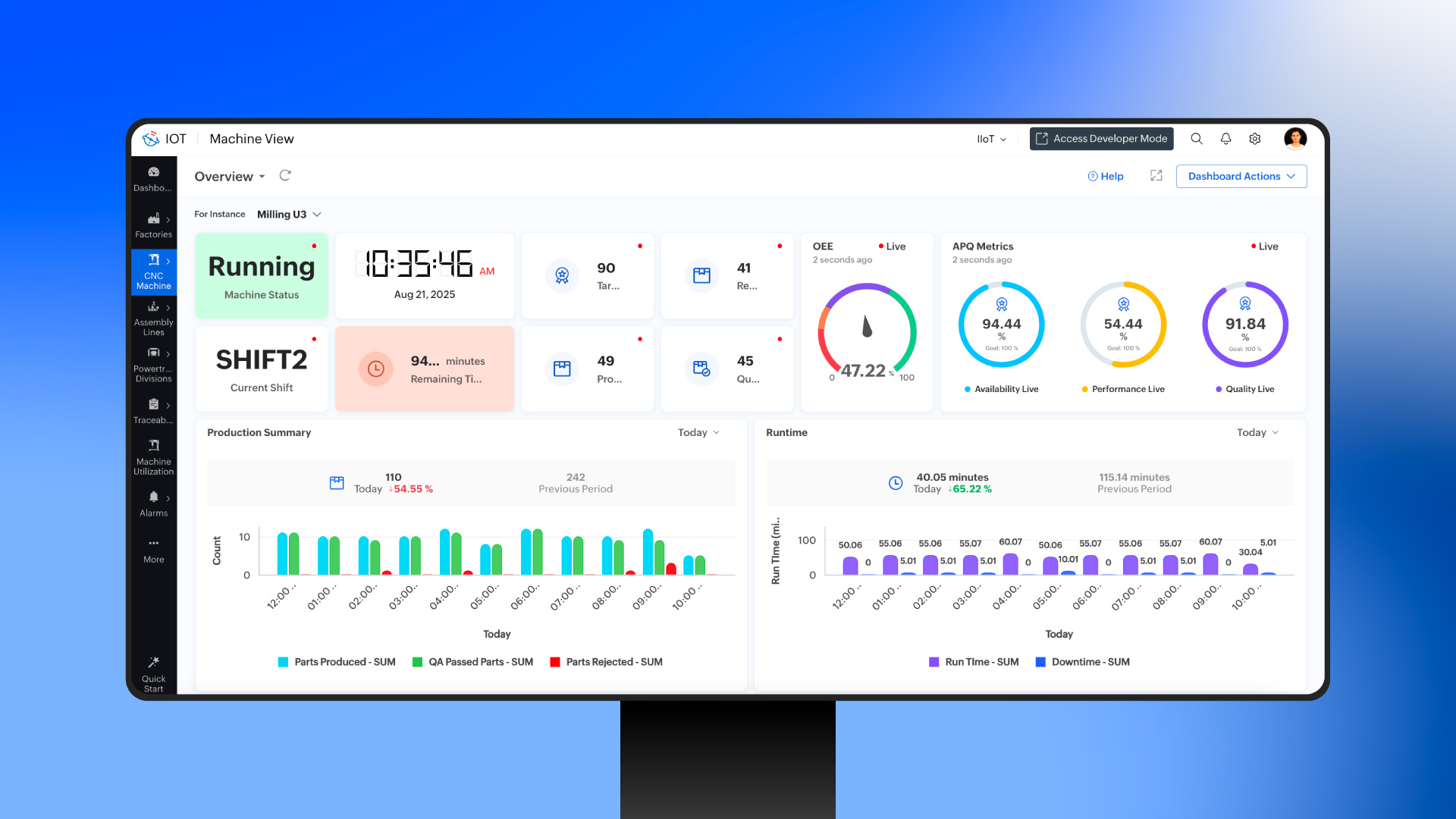

The primary goal of deploying IIoT within a manufacturing set-up is to digitize the assembly or production lines. IIoT enables manufacturers to connect multiple production lines and machines, acquire data at different stages of production from several disparate sources, and develop capabilities like remote monitoring, edge analytics, and predictive maintenance, and digital twin. The deployment of the latest technologies helps businesses gain control over their machines and processes.

Shop Floors & Operations

Industrial IoT can connect machines, tools, and sensors in the workplace to offer process engineers and managers much-needed visibility into production. Additionally, by integrating the tools used by the operators with the machines involved in the production, Industrial IoT applications can give supervisors and plant managers a real-time view on the overall yield. This level of visibility is often employed by manufacturers to spot bottlenecks, find the basis explanation for problems, and improve at a faster rate.

Supply Chain

Today’s supply chain management cannot analyze or understand the machine and part/batch-level data across the supply chain, limiting the manufacturer’s ability to manage its supplier base as an integrated platform. But, Industrial IoT has the potential to solve such manufacturing and supply-chain based challenges. IIoT sensors can potentially be placed on every tool, part, and asset within a manufacturing supply chain, creating operational visibility and providing insights that can significantly improve performance and reduce inefficiencies.

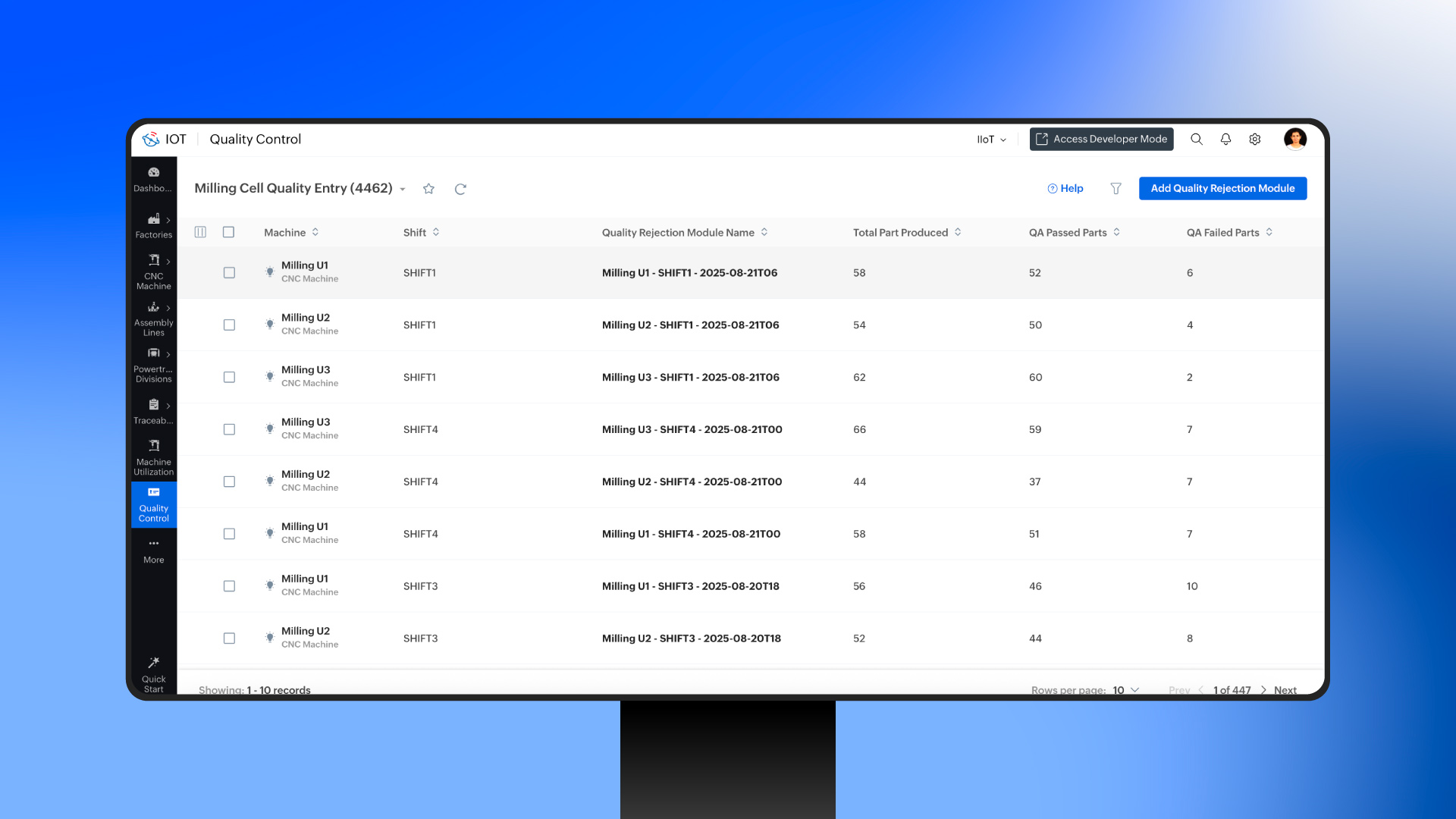

Quality Management

Quality control is fundamental in every industry, but in manufacturing, it’s hyper-critical. With IIoT connectivity, manufacturers can now collect granular critical data points along the production line, aggregate product data, and other third-party syndicated data through sensors across various stages of a product cycle. It, in turn, assures a proactive quality assurance approach, checked against raw materials availability, additional units scheduled and added to the production process, to diagnose and prevent defects much earlier in the process for peak production throughput and repeatability alongside reduced costs and waste – all without involving human interaction between production, operations, and scheduling. Moreover, if used in the final product, the IIoT device can provide data about the customer sentiments on using the product. All of these inputs can later be analyzed to identify and correct quality issues, which leads to significant improvement.

Safety & Security

Workplace safety is essential to achieving optimal operation, avoiding substantial production interruptions, and importantly, protecting employees. With IIoT, manufacturers get visibility of the equipment allowing manufacturers to view key performance indicators in not only production but also safety compliance. It, in turn, allows the manufacturers to be proactive in being able to spot possible safety gaps in the process.

And lastly, why should manufacturers resort to IIoT? Why is it beneficial?

Reduced downtime with Predictive Maintenance

The majority of the manufacturing plants, today, see maintenance as a costly challenge. More often than usual, manufacturers using legacy compressors, condensers, conveyors, or motors, face a breakdown or maintenance need as they are old and traditional. Under such cases, they often end up duplicating the spares on-site as these parts are either no more stocked or available in the market. When anomalies or breakdowns happen without warning, it stalls the entire production process for days or weeks until resolved and replaced with new parts.

The majority of the manufacturing plants, today, see maintenance as a costly challenge. More often than usual, manufacturers using legacy compressors, condensers, conveyors, or motors, face a breakdown or maintenance need as they are old and traditional. Under such cases, they often end up duplicating the spares on-site as these parts are either no more stocked or available in the market. When anomalies or breakdowns happen without warning, it stalls the entire production process for days or weeks until resolved and replaced with new parts.

With IIoT, predictive maintenance enabled by wireless sensors can alert managers whenever a machine is down or operating outside its normal parameters. By predicting anomalies well in advance, it gives an upper hand to the operations team, who now can fabricate the replacement parts way before the machines break down. It helps to reduce the unplanned shutdowns and increase uptime by up to 20%, according to Deloitte. Over time, as the sensor network collects more data for analysis, the predictions become more refined and precise, allowing for even better planning.

Tracking & Monitoring for Asset Safety

IIoT based sensors come with an ability to track assets and its locations that can prove to be a boon for Food & Beverages, Pharma, and other manufacturers, to keep a track on their delivery, while in transit. It also means not only it tracks the container/fleet in transit but also the consignment and safeguard other valuable equipment while maintaining in-time and damage-free delivery.

IIoT based sensors come with an ability to track assets and its locations that can prove to be a boon for Food & Beverages, Pharma, and other manufacturers, to keep a track on their delivery, while in transit. It also means not only it tracks the container/fleet in transit but also the consignment and safeguard other valuable equipment while maintaining in-time and damage-free delivery.

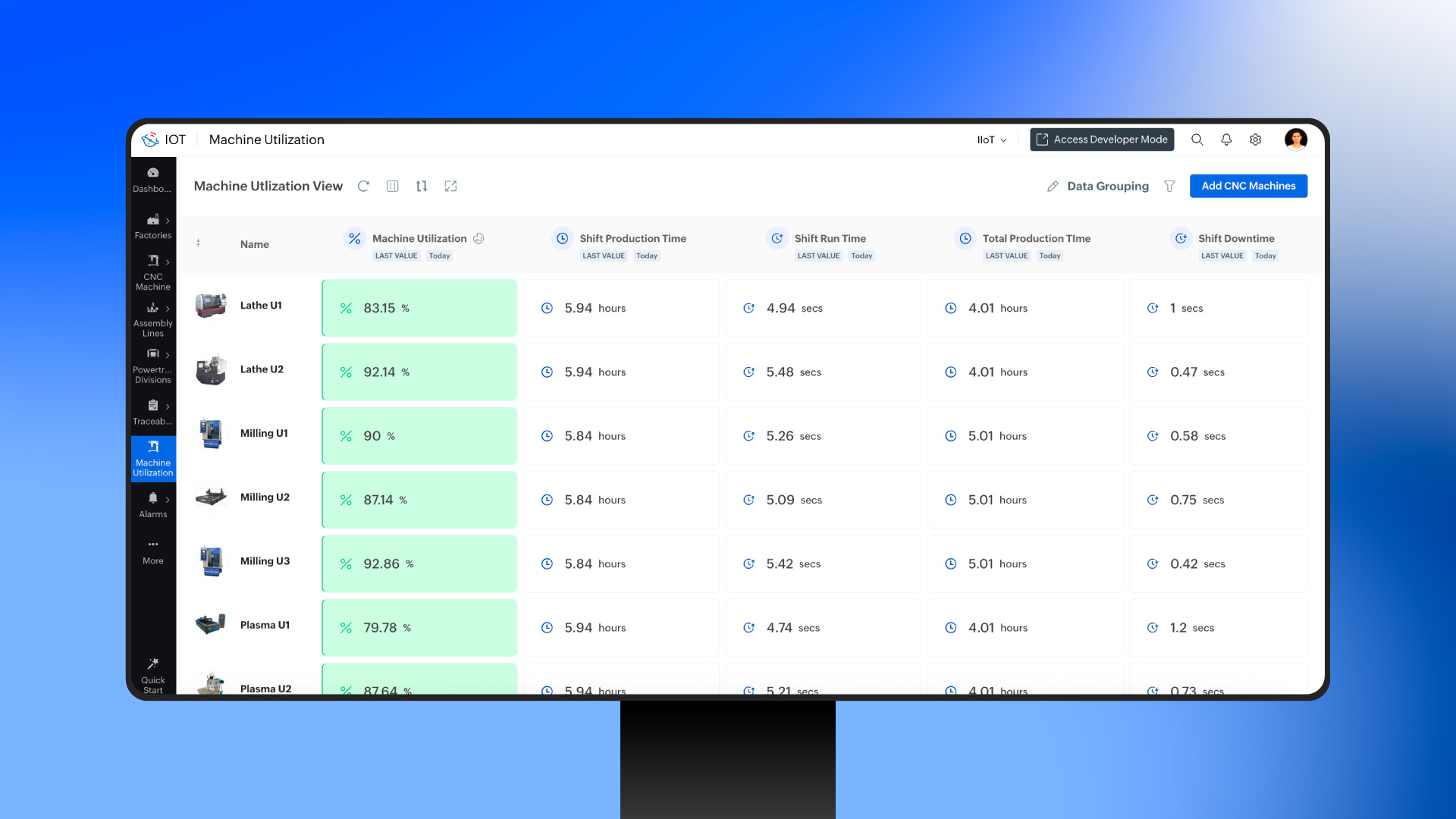

Asset Utilization & Improved OEE

While sensors help to monitor equipment, tracking locations, and predicting maintenance needs, they also reveal how much each machine ran throughout the process. With data like these, managers would be able to strategize well to improve productivity and thus, OEE – a productivity measurement that combines downtime, production rate & quality. It can resolve the issues without a multimillion-dollar expenditure, even across the shifts & processes. In fact, productivity improvements can likely grow from 15% to 50%.

While sensors help to monitor equipment, tracking locations, and predicting maintenance needs, they also reveal how much each machine ran throughout the process. With data like these, managers would be able to strategize well to improve productivity and thus, OEE – a productivity measurement that combines downtime, production rate & quality. It can resolve the issues without a multimillion-dollar expenditure, even across the shifts & processes. In fact, productivity improvements can likely grow from 15% to 50%.

Quality Control for Product Development

In a manufacturing process, faults and shortcomings in the final product upsurge expenditure and overburden the employees. To mitigate these issues, manufacturers can utilize the IIoT features. By retrofitting sensors, manufacturers gather data about their equipment’s entire working mechanism and can predict the expected output from each unit. The data enables managers to analyze the efficiency, effectiveness, and accuracy of the system. It also helps in identifying potential bottlenecks in their product that allows managers to create a better version of the products.

In a manufacturing process, faults and shortcomings in the final product upsurge expenditure and overburden the employees. To mitigate these issues, manufacturers can utilize the IIoT features. By retrofitting sensors, manufacturers gather data about their equipment’s entire working mechanism and can predict the expected output from each unit. The data enables managers to analyze the efficiency, effectiveness, and accuracy of the system. It also helps in identifying potential bottlenecks in their product that allows managers to create a better version of the products.

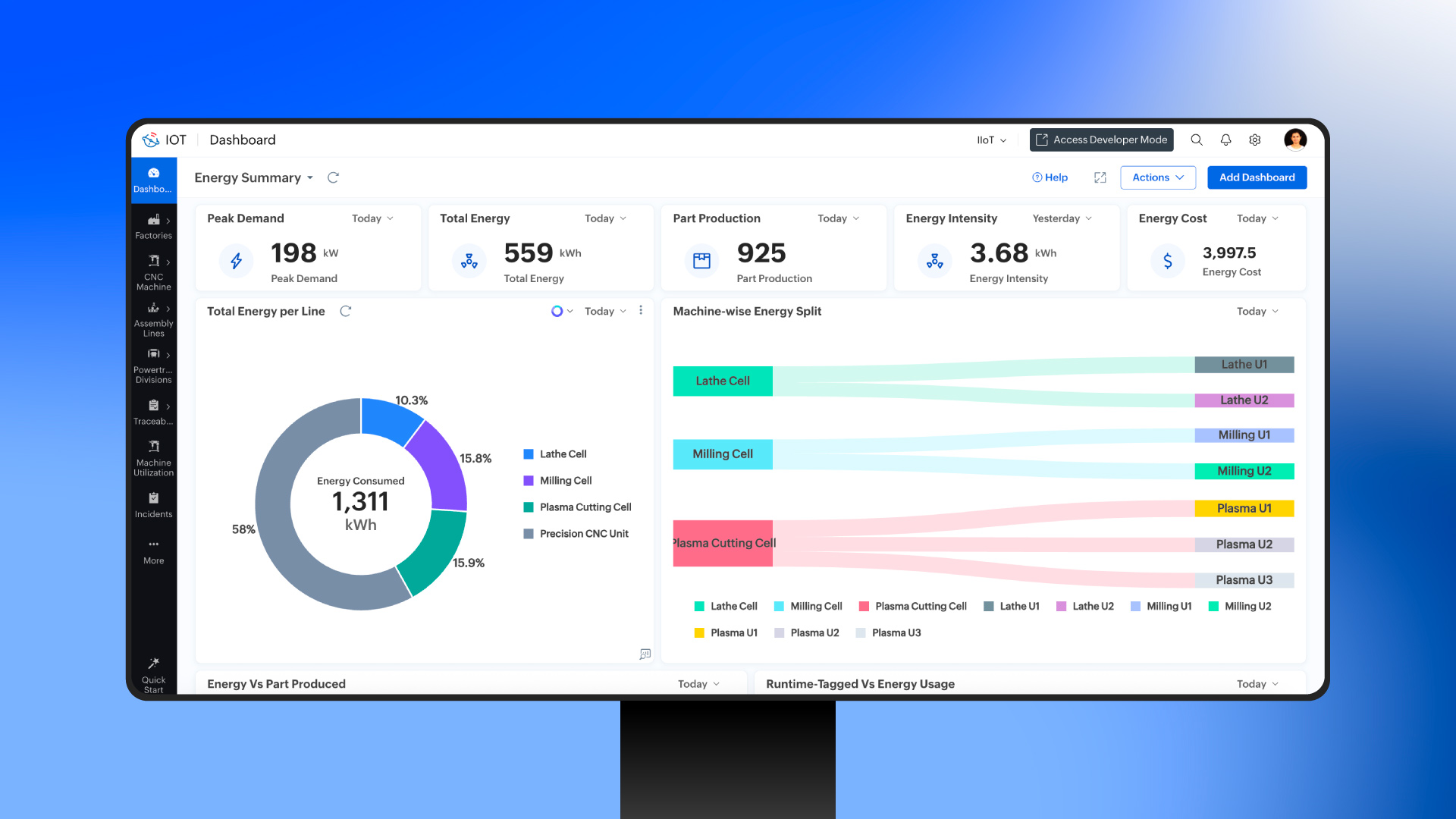

Cost Savings through Energy Management

Industrial IoT applications can help manufacturers track, monitor, and collect energy insights such as overall savings on maintenance expenses, energy consumed per production batch, etc. thus, allowing manufacturers to identify the areas of energy loss or increasing cost and take appropriate actions. This type of architecture is finding increasing adoption in manufacturing environments, making buildings smarter, more sustainable, and more efficient.

Industrial IoT applications can help manufacturers track, monitor, and collect energy insights such as overall savings on maintenance expenses, energy consumed per production batch, etc. thus, allowing manufacturers to identify the areas of energy loss or increasing cost and take appropriate actions. This type of architecture is finding increasing adoption in manufacturing environments, making buildings smarter, more sustainable, and more efficient.

As more manufacturers install sensors and start collecting data, it will not only bring efficiency in the overall process but also develop new IIoT use cases based on the needs. This trend will continue for years to come and thus, revolutionizing the manufacturing sector completely, for its best.

Learn more on IIoT or start a free trial or request a demo today at Zoho IoT!