Warehouse Management

Understanding warehouse management strategies and software

Warehouse management is the process of planning, arranging, and organizing goods and materials in a warehouse. This involves,

- Managing new orders and their corresponding stocks

- Maintaining equipment

- Shipping orders, receiving, picking, and packing

- Arranging the goods and keeping a track of the movement of the goods and the employees

Optimizing these processes is essential for daily inventory management. An efficient warehouse management system is a key component for any commodity-based business to be successful in the long run.

For B2C and B2B companies, this is not just another task. It’s also a benchmark that companies strive to excel at. Attaining this benchmark through streamlined warehouse practices has become a strategic weapon that many companies are using to enhance their competitive position. It could be the factor to mess up your business or propel it to meet customer expectations while also managing logistical and supply chain operations.

What makes a warehouse management strategy successful has evolved, and there are many factors to consider when planning and implementing a new warehouse management strategy.

A single warehouse vs. multiple warehouses

When it comes to managing warehouses, scaling up does not happen in defined increments. This is an often-overlooked problem when understanding and managing warehouses. Let’s take a look at what strategies can be used when managing warehouses that are at our disposal.

Single warehouse management

Businesses generally start with a single warehouse and then scale accordingly. With this, the main task is to manage all the goods and resources within a limited space. It’s important to make the most of every square meter available as you don’t want to waste space on products that are not in high demand, leaving no space for products that are needed. This will increase your carrying costs because you’ll have to hold the stock in your warehouse for a long time.

How to reduce your warehouse costs?

1. More space, less money

Having a warehouse with more height can save you money on rental costs. Evaluate your product and what kind of space it needs, and try to find ways to avoid adding additional square feet. It’s possible you can accomplish the same storage goals with tall shelving or higher ceilings.

2. Manage and organize your inventory

Learn more about the business and have a good grasp on customer needs. These needs are a roadmap on how to manage your stock. Here are a few tips:

- Know the demand for each product and stock accordingly.

- Categorize them into most selling items and least selling items.

- Put the items that are often sold together next to each other.

- Understand seasonal production and demands.

3. Use SKUs and barcode scanners

One of the common mistakes made when maintaining a warehouse is losing track of the number of products that are present in the warehouse. A Stock Keeping Unit (SKU) is a number given to each item. It’s used not only to identify the product and its details (such as color, size, style, price, manufacturer, and brand) but also for tracking it. Using the right management system and tools will help you keep track of the number of products in your warehouse and understand in advance which products are running out of stock. Barcode scanners are used to reorder parts, give detailed product information, and perform other tasks within the warehouse faster and more accurately than doing so by hand.

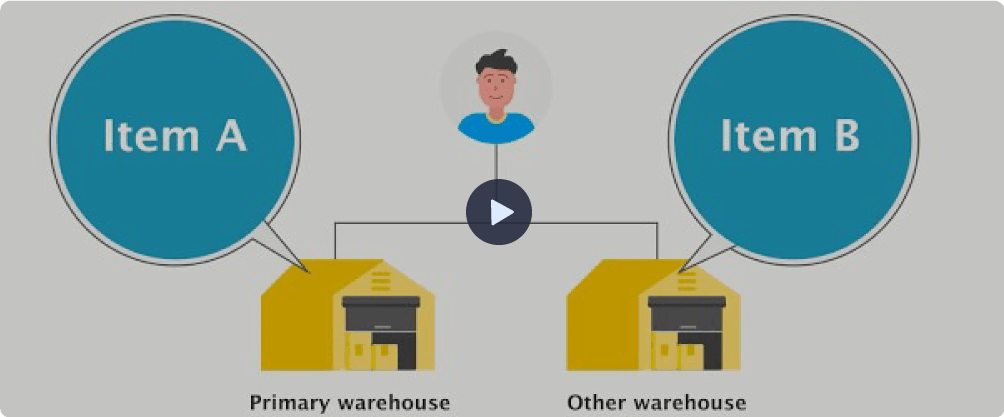

Multiple warehouse management

As your business grows, it’s necessary to add new warehouses to handle new, complex operations and more inventory. While making these expansions, it’s critical to keep using the previous strategies to minimize the increased logistical and complex challenges.

How to handle multiple warehouses?

-

Know where everything is: With multiple warehouses, it’s a good idea to drill down into each location and know how many items you have at each one. This way, you can quickly find when it’s time to reorder more to avoid stock outs and more complexity.

-

Different locations, different needs: While managing your warehouses, each location will have its own sales figures, and no two locations will have the same output. Demand will be different based on the differences in the customer base.

-

Transfer orders: This plays a major role when you have multiple warehouses. You might notice that you have a high demand for a particular product in one location and not in another. If you are in danger of running out at the first location, you can put in a transfer order from the second location and prevent a stockout.

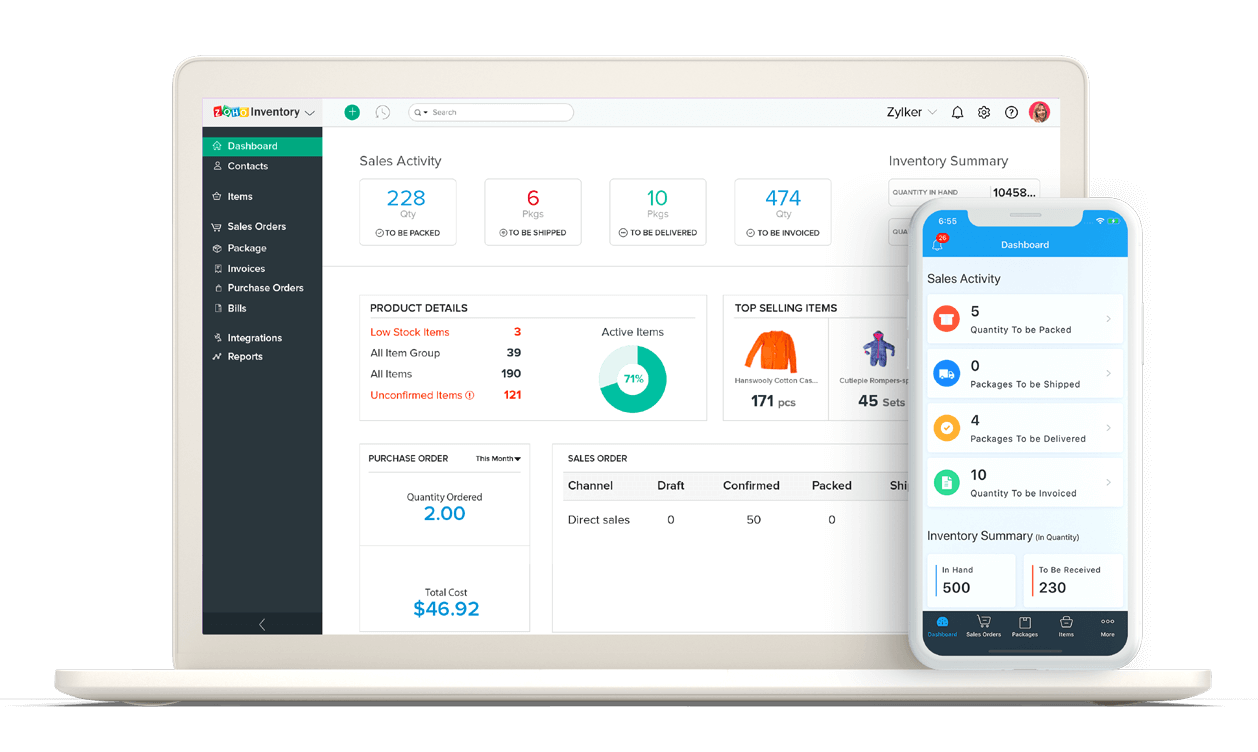

Warehouse Management System (WMS)

A warehouse management system is typically a software application that allows you to control, manage, support, and optimize your day-to-day warehouse operations.

-

Know the flow of your business and choose software accordingly. Not all WMS provide the same functions, and you should choose the one best suited for your business.

-

If your business is growing and your WMS is unable to keep up, then you could face major logistical problems. Your software needs to be able to handle all of your incoming items so the records are not confused and you know where items should go.

If you are facing warehouse management issues, the solution is to find better software. No matter how the economy is doing, a good WMS is customizable to your specific business needs. Finding the right one could mean the difference between success and failure.

Inventory Control

Inventory Control Warehouse Management

Warehouse Management Multichannel Selling

Multichannel Selling Order Management

Order Management Order Fulfillment

Order Fulfillment Insightful Reports

Insightful Reports