Benefits of IoT in generator monitoring

Our solution fits right into your existing utility systems, or we can assist you in selecting the right sensors and gateways to speed up data communication to your dashboard. With IoT based water monitoring, you could:

Real-Time Monitoring and Rapid Response

Enhanced Worker Safety

Increased Generator Lifespan

Reduced Operational Expenses

Improved Decision Making

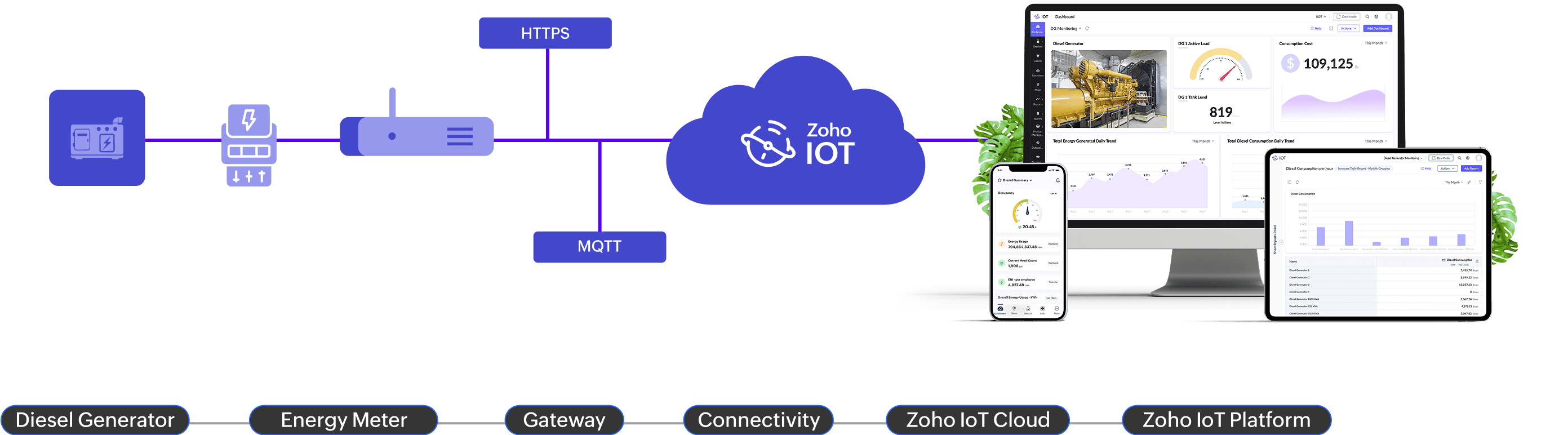

A Complete IoT Platform for Remote Generator Monitoring and Control

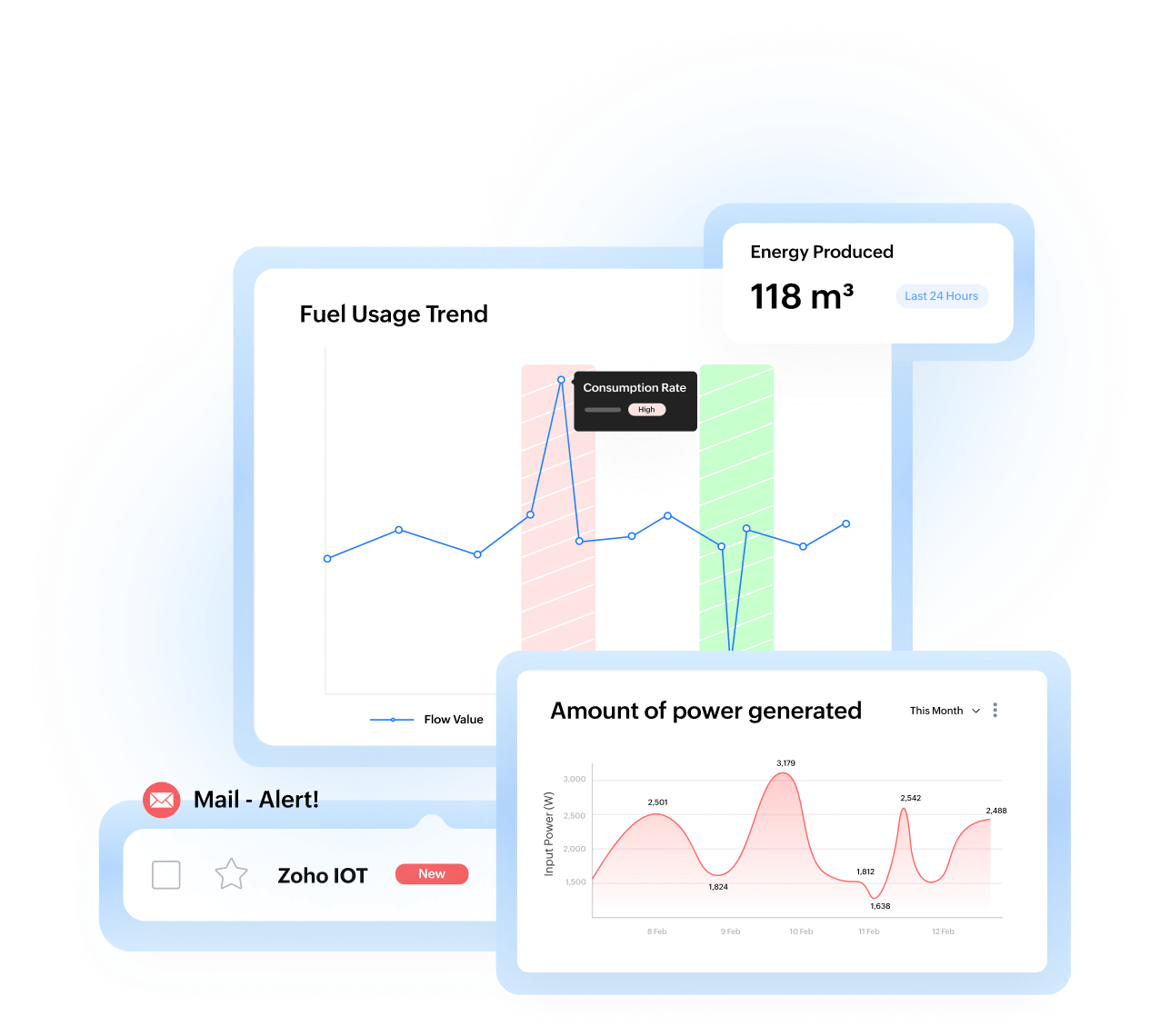

Real-time monitoring

Gain complete visibility into your generator fleet with live dashboards and health metrics accessible from anywhere. Monitor generator status, power output, fuel levels, and system health in real-time to ensure readiness and prevent unplanned downtime.

- Remote Dashboard Access

- Customizable dashboards

- Live Data Streaming

- Alerts via SMS/Email/Push Notification

Fuel level and leakage monitoring

Continuously track fuel levels to avoid dry runs and unscheduled downtime. Smart IoT sensors detect abnormal drops, signalling possible leaks or theft. Enabling efficient refuelling strategies, reducing fuel wastage and costs. It's particularly valuable for remote and multi-site installations.

- Fuel Level Monitoring

- Fuel Leakage Detection

- Fuel Theft Detection

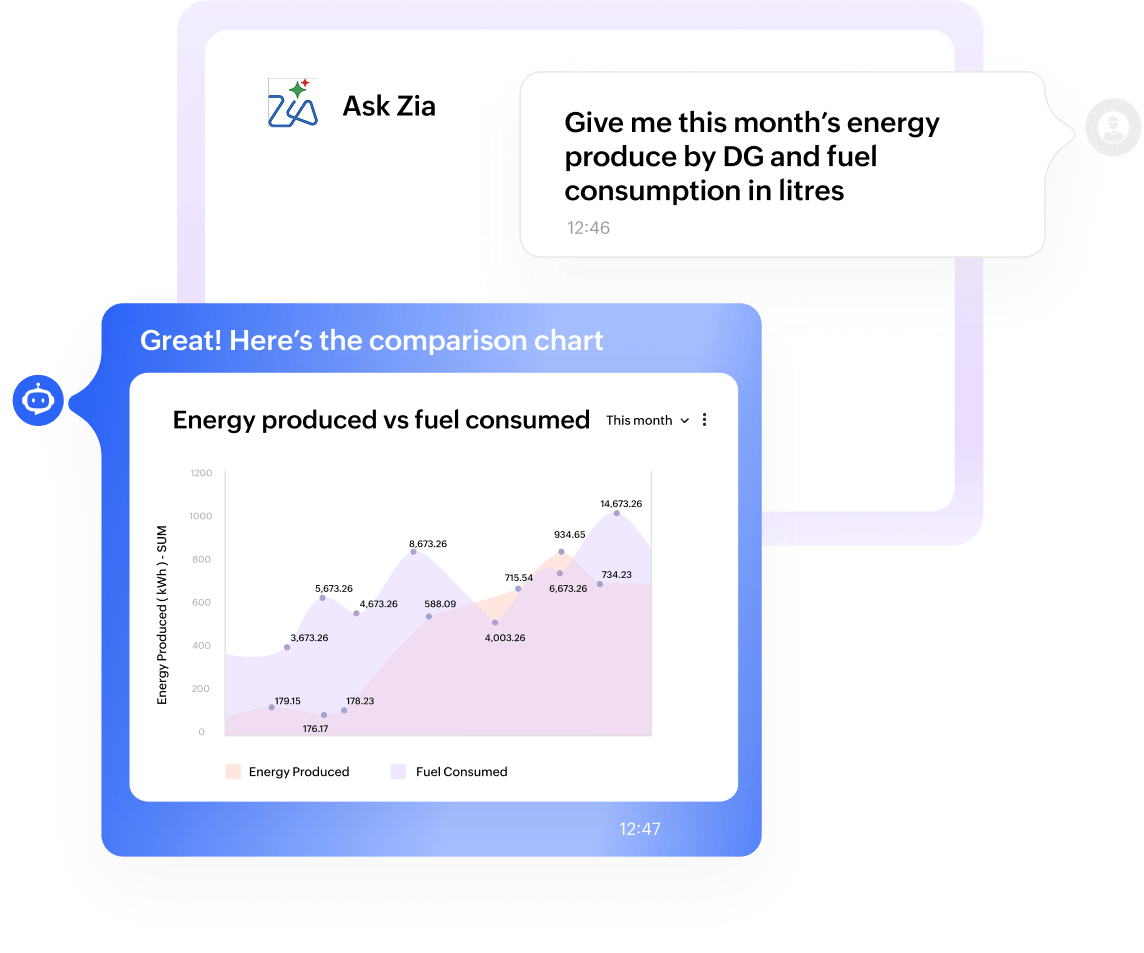

Energy Monitoring

Get detailed insights into your generator’s energy performance, efficiency, and cost-effectiveness. Correlate power output with fuel use to calculate cost per unit and uncover areas for optimization. Maintain power quality through consistent voltage.

- Live Energy Monitoring

- Energy Generated Reports

- Fuel-to-Energy Cost Insight

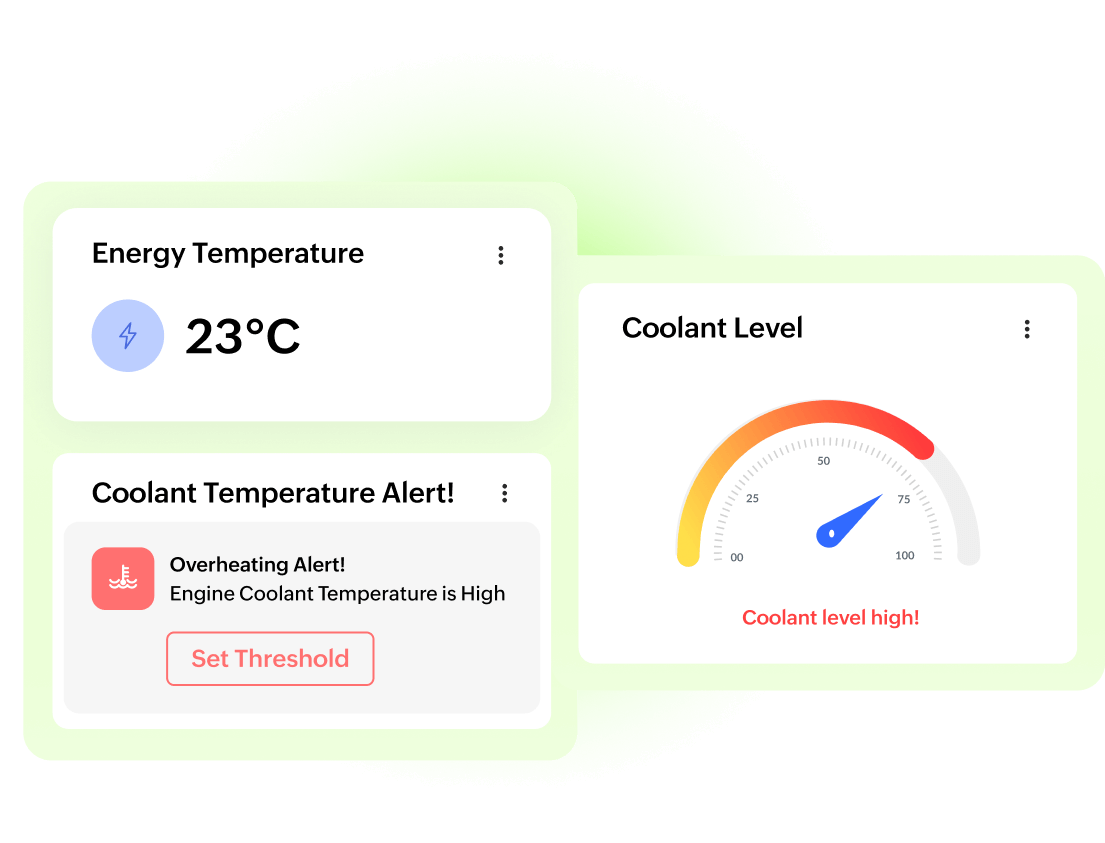

Temperature and Coolant Monitoring

Protect your generator from overheating with proactive temperature and coolant monitoring. The system tracks engine temperature, coolant levels, and coolant temperature in real time. Maintaining optimal conditions and extending engine lifespan.

- Engine Temperature Monitoring

- Coolant Level Monitoring

- Coolant Temperature Alerts

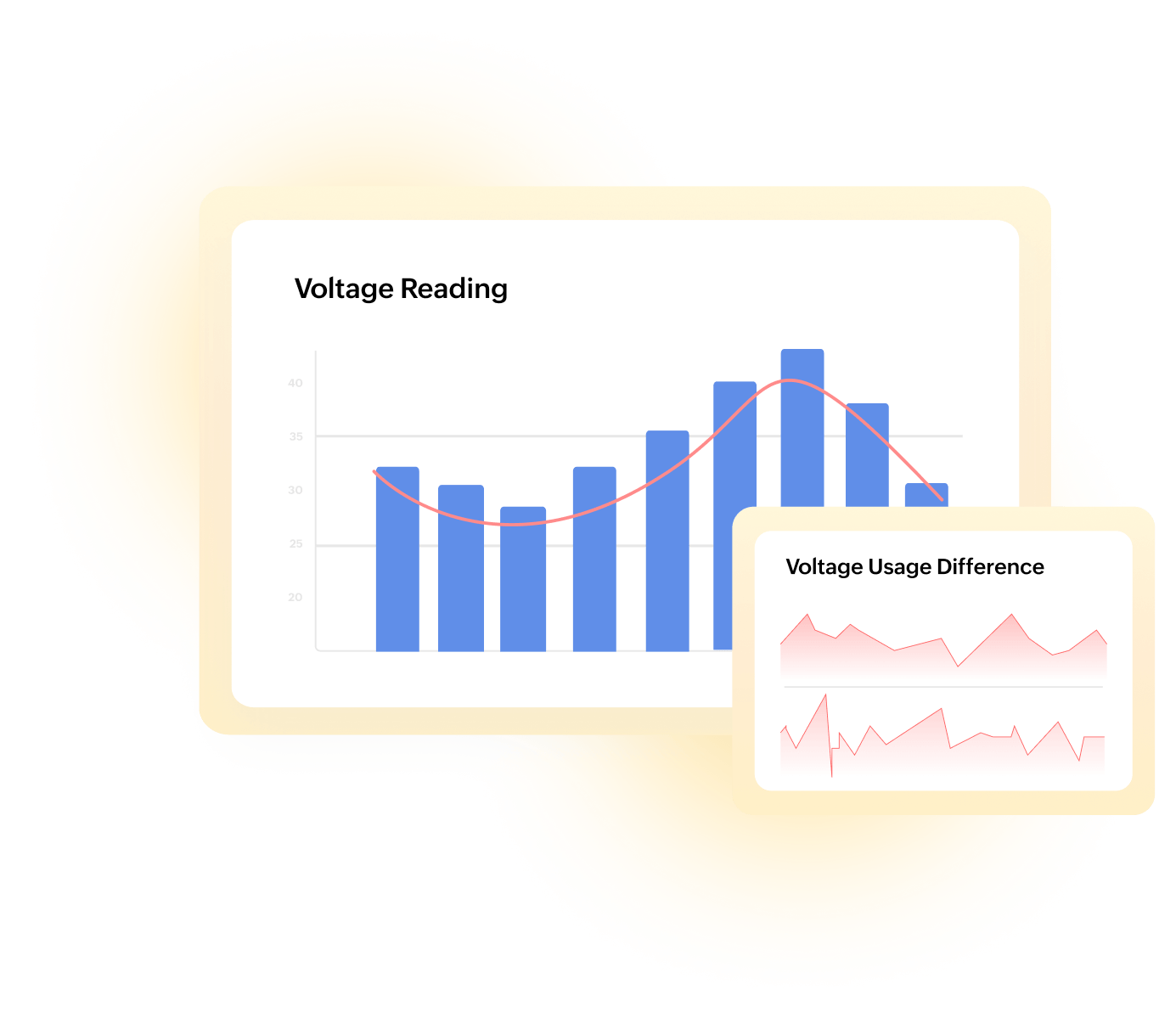

Battery monitoring

Monitor fluctuations in output frequency and voltage to maintain safe power delivery. Identify early signs of battery degradation or load instability. This protects sensitive equipment and guarantees consistent generator readiness.

- Battery Voltage & Health

- Frequency and Voltage Fluctuation Detection

- Energy Parameters Monitoring

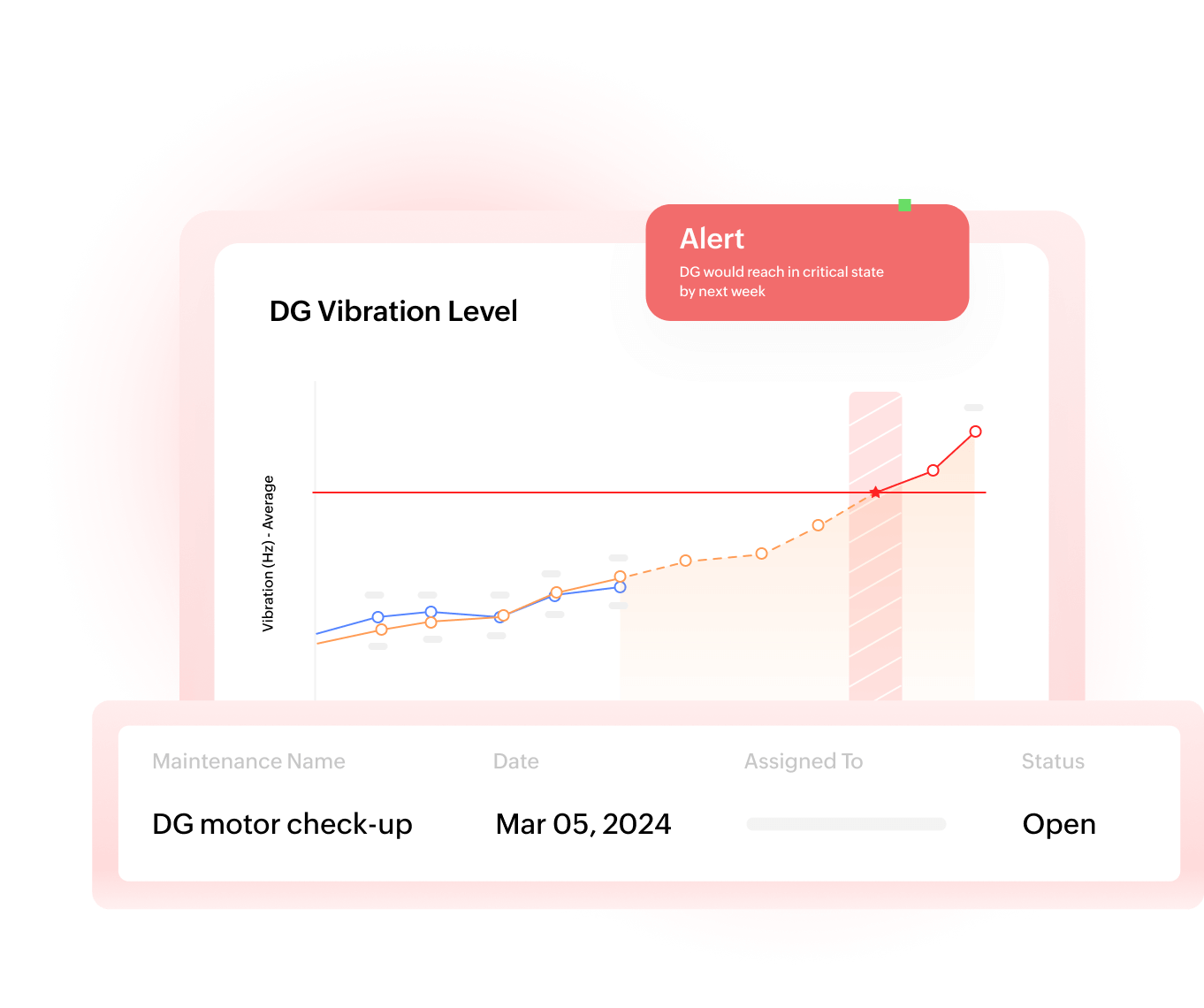

Engine parameters monitoring

Monitor engine vibration and noise to detect mechanical wear or imbalance before it escalates. Early identification of issues like loose components or belt slippage helps reduce downtime and repair costs.

- Vibration Analysis

- Noise Monitoring

- Mechanical Fault Prediction

Maintenance Management

Automate service planning with predictive and preventive maintenance tools. Set rules based on engine hours, condition thresholds, or usage trends to trigger reminders. Reduce emergency repairs and extend generator life by servicing only when needed.

- Preventive Maintenance

- Automated Maintenance Scheduling

- Predictive Fault Detection

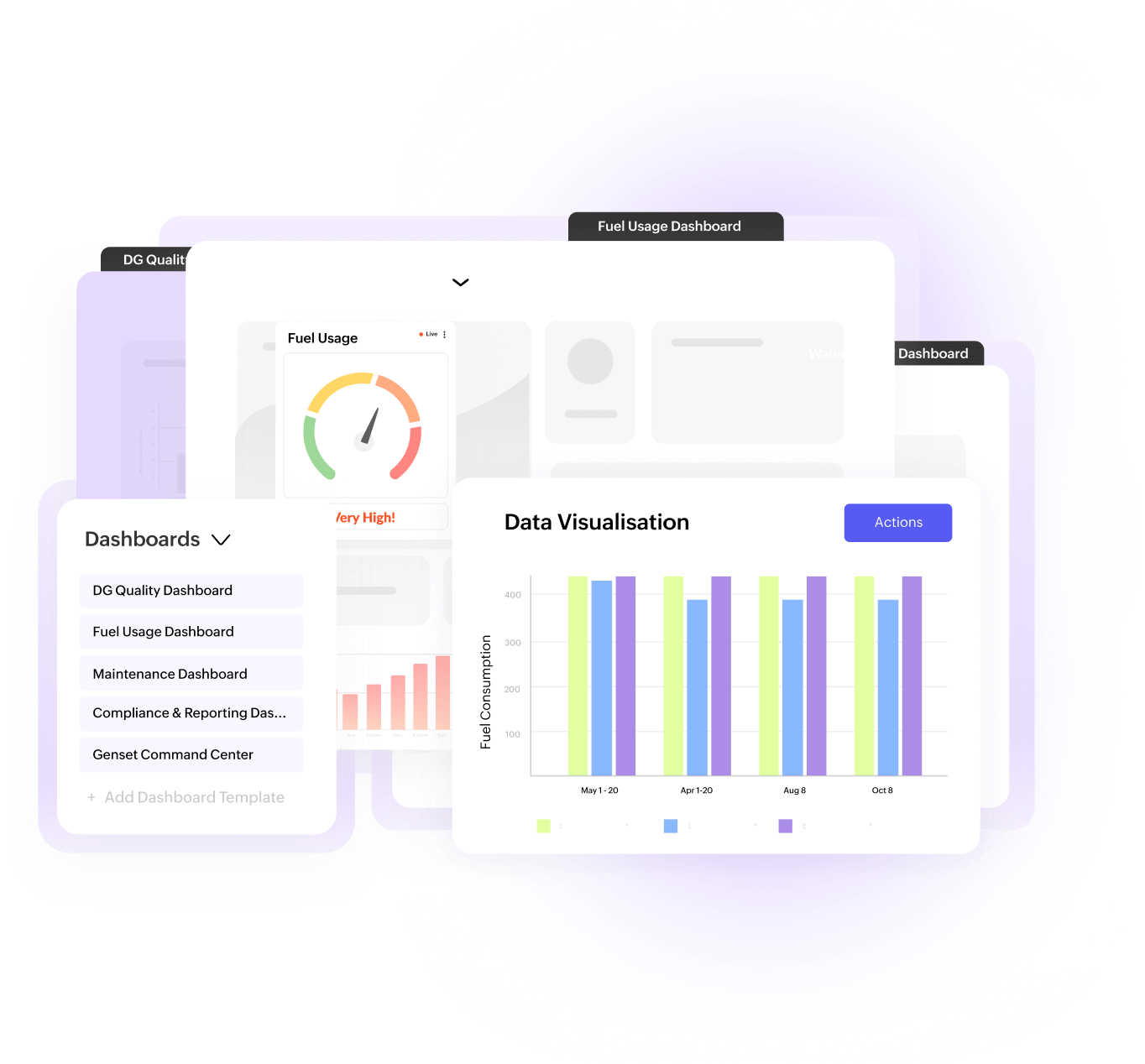

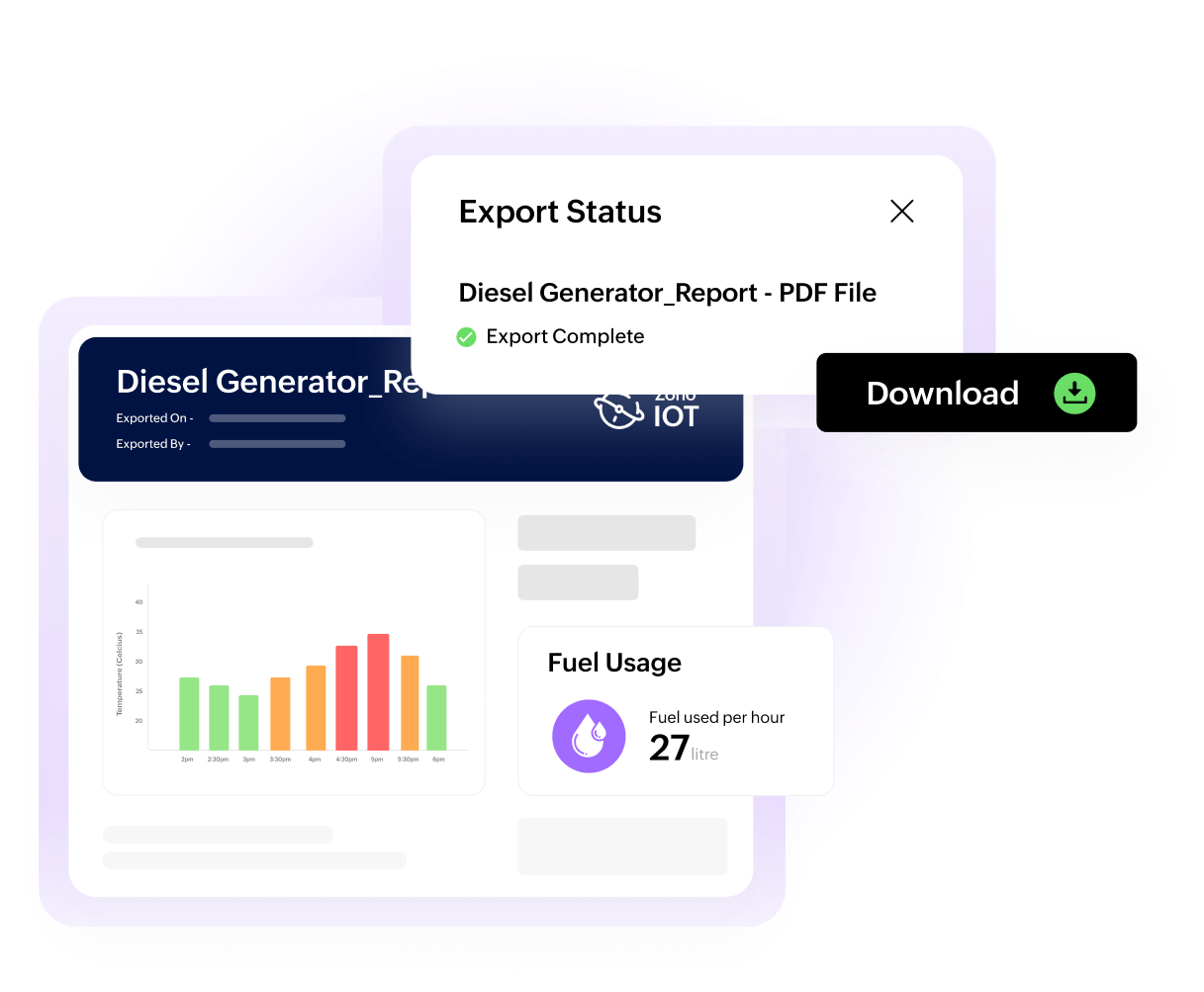

Reports and analytics

Access historical trends and detailed reports on generator health, uptime, fuel efficiency, and performance. Schedule reports for daily, weekly, or monthly across locations. These insights help you make data-backed operational and budgeting decisions.

- Scheduled Reports

- Customizable Dashboards

- Generator Performance Trends

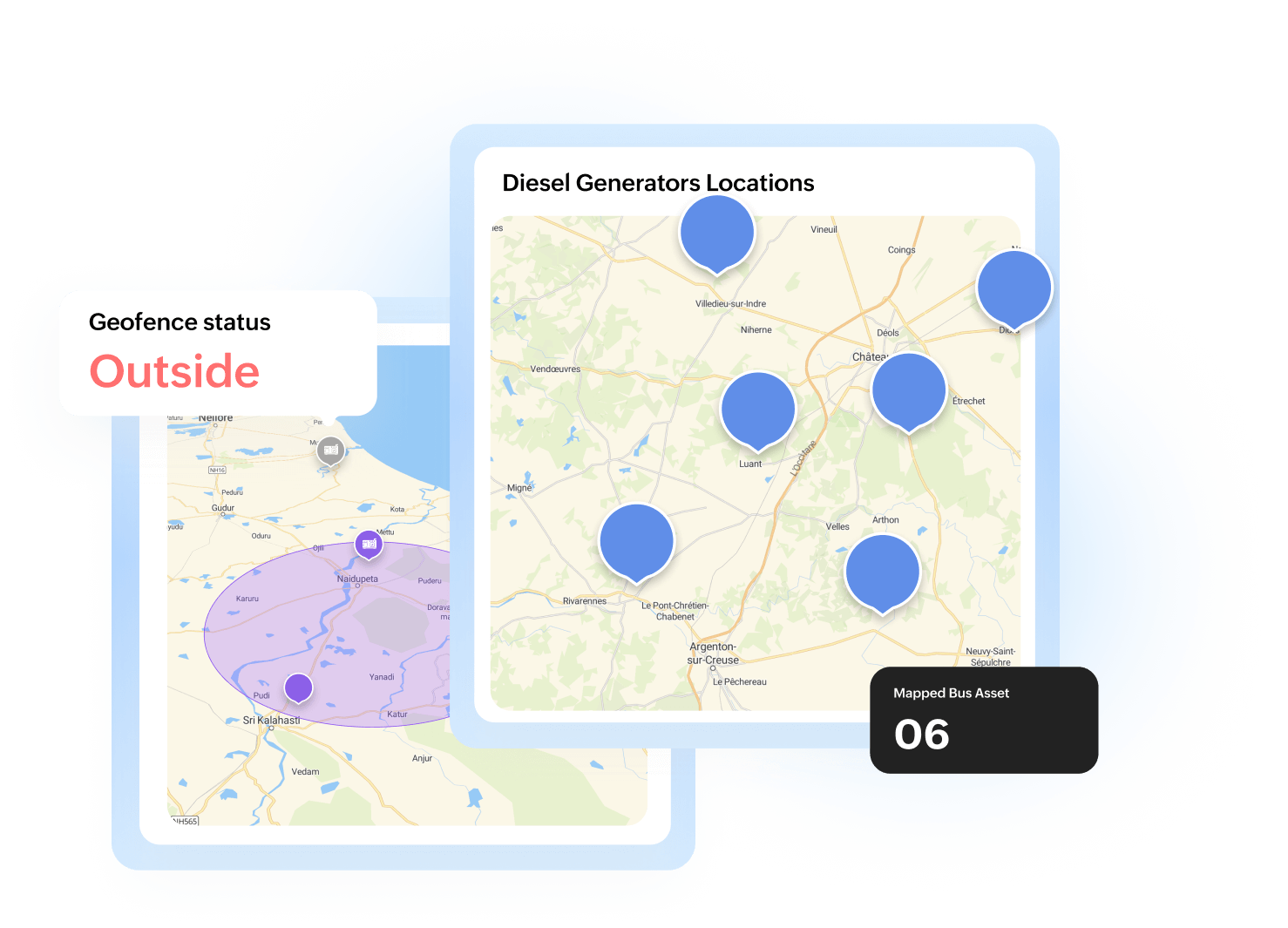

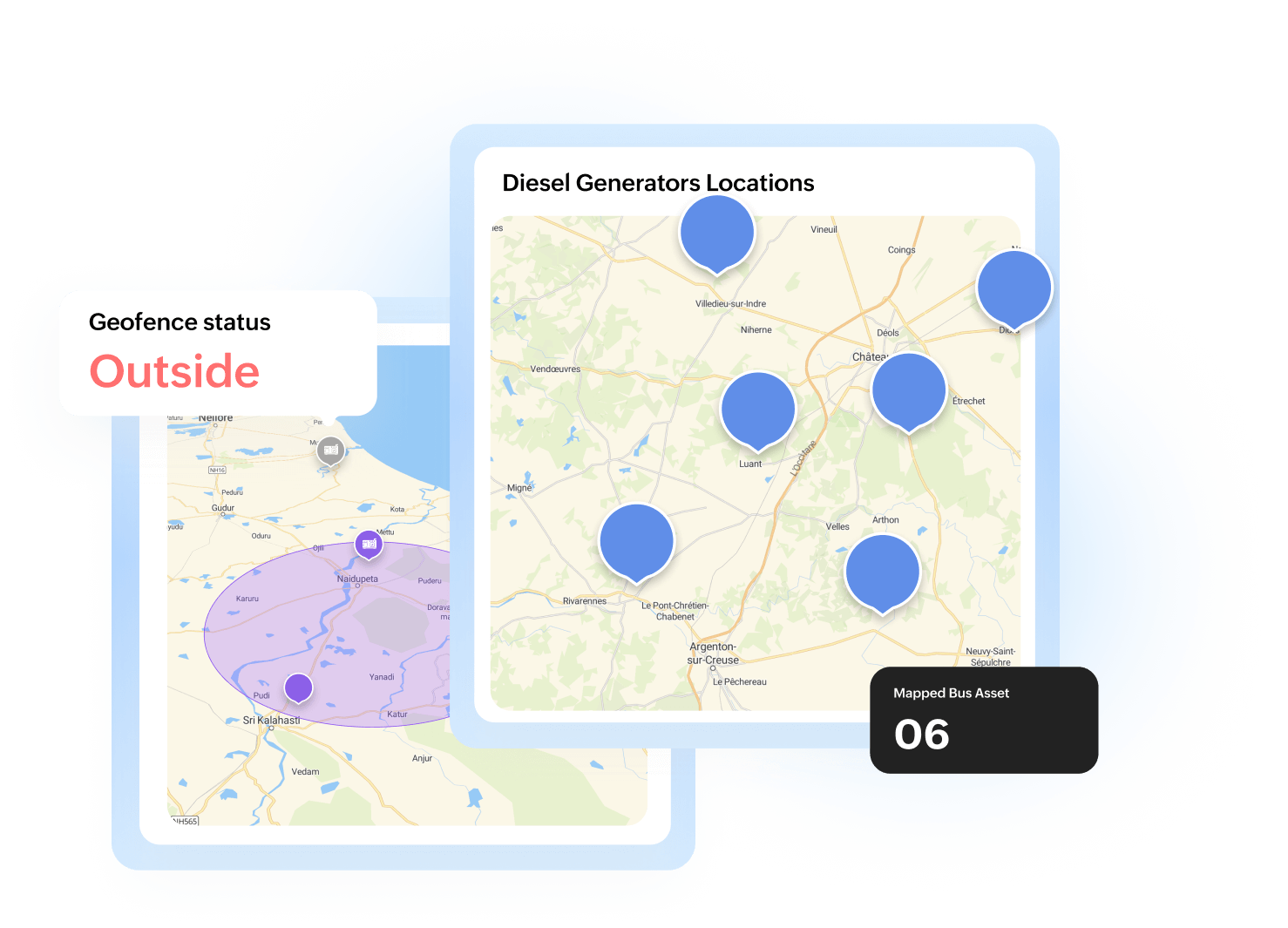

Location & Asset Tracking

Track your generator assets in real-time. Geofencing provide security by alerting you when a genset moves beyond set boundaries. This feature is critical for mobile, rental, or site-deployed generators. It ensures accountability and prevents loss or misuse.

- GPS Location Monitoring

- Geofencing Alert

- Movement Logs