Finance Free Apps

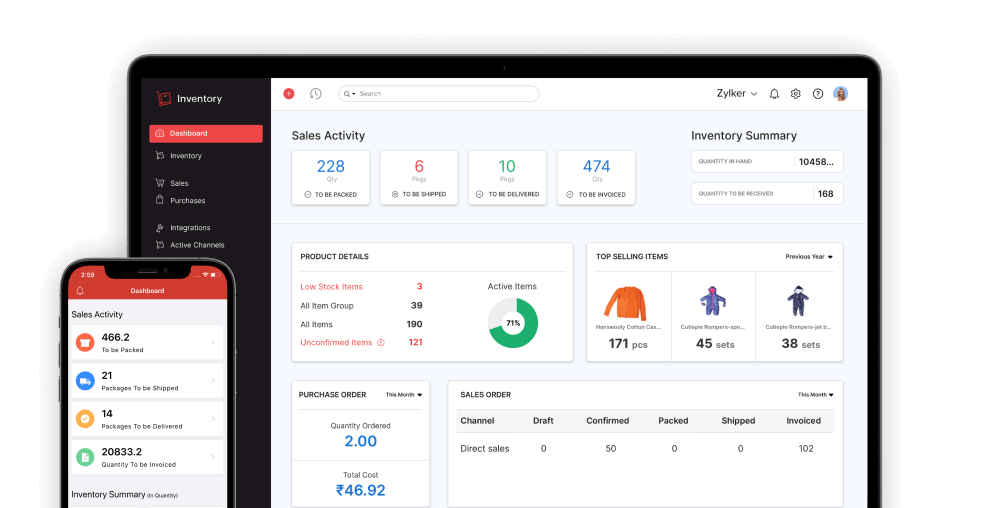

Inventory

- SKU Generator

- Purchase Order Generator

- Calculate Reorder Point

- Economic Order Quantity

- Break-even Point Calculator

- Inventory Turnover Ratio

- Packing Slip Generator

- Barcode Generator

- Shipping Label Generator

- Wholesale price calculator

- Lead Time Calculator

- Average Inventory Calculator

- Inventory Cost Calculator

- Finished Goods Inventory Calculator

- Beginning Inventory Calculator

- Handling Fee Calculator

Billing

Finance & Payroll

- HMRC Furlough Claim Calculator

- Income Tax Calculator

- Paycheck Calculator

- India GST Calculator

- UK VAT Calculator

- UK Flat Rate Calculator

- Corporation Tax Calculator

- Financial Report Templates

- Free Project Cost Quote Calculator

- Form W-9 Generator

- Payslip Generator

- NPS Calculator

- EPS Pension Calculator

- Gratuity Calculator

- Statutory Bonus Calculator

- HRA Exemption Calculator

Expense